Case Study: How an Iron Ore Mine Solved Recurring Lagging Failures

Cutting Downtime, Protecting Belts – The Elastotec Advantage

At an Iron Ore mine in Western Australia, recurring failures with their direct-bond ceramic lagging were costing time, money, and reliability.The lagging typically lasted just nine months before failure, with frequent tile loss leading to unplanned shutdowns and increased risk of belt damage.

Over a five-year period, the mine faced five pulley refurbishments and changeouts due to lagging failures – prompting them to seek a more reliable solution.

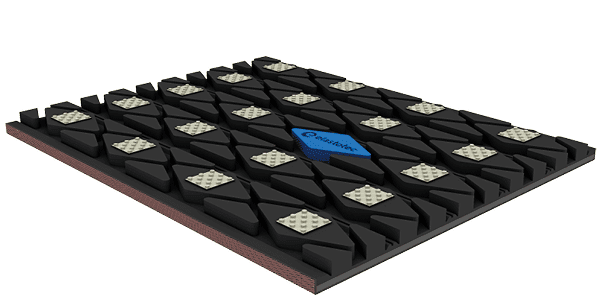

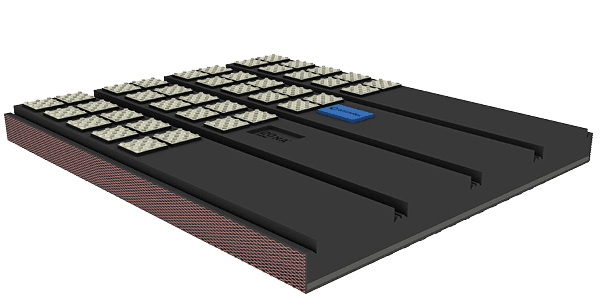

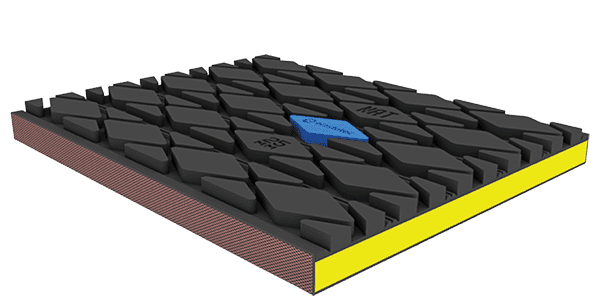

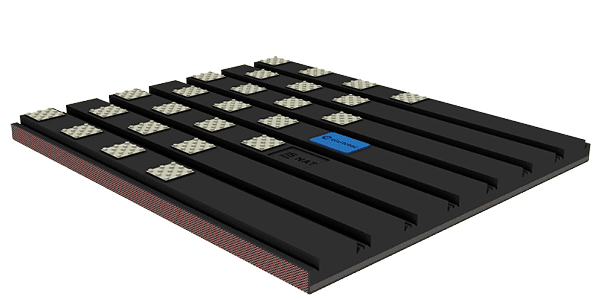

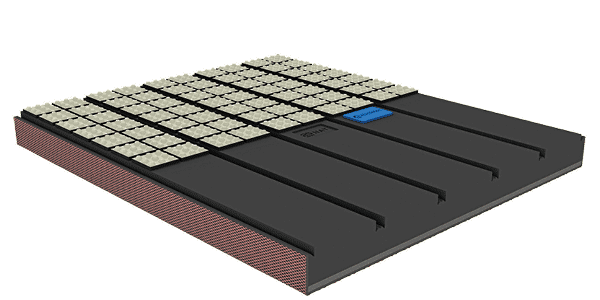

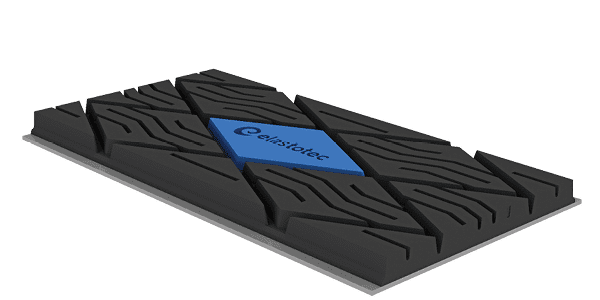

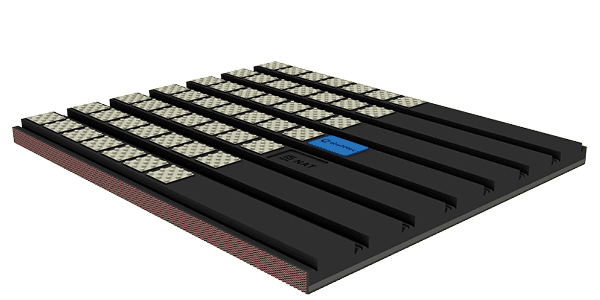

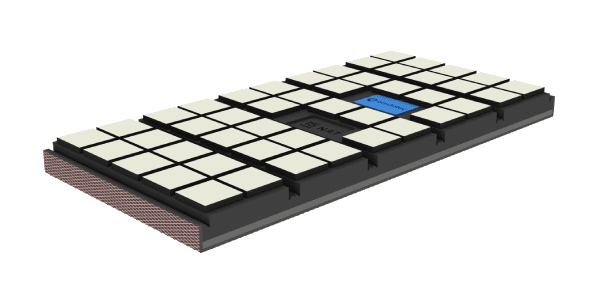

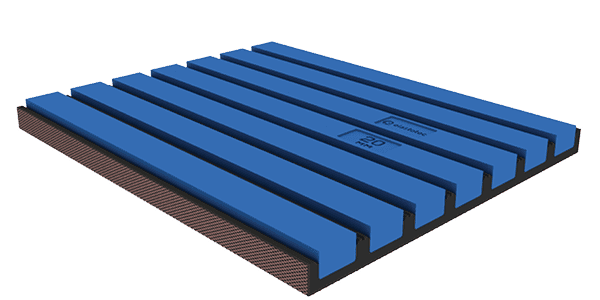

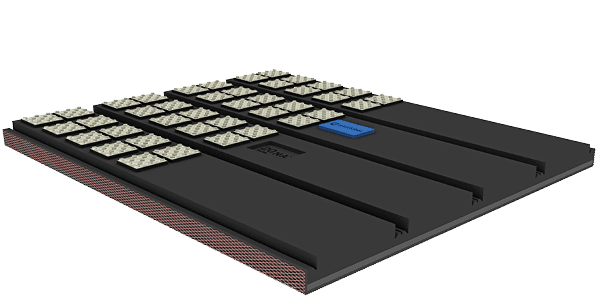

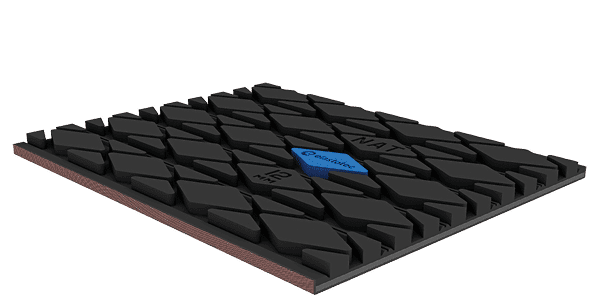

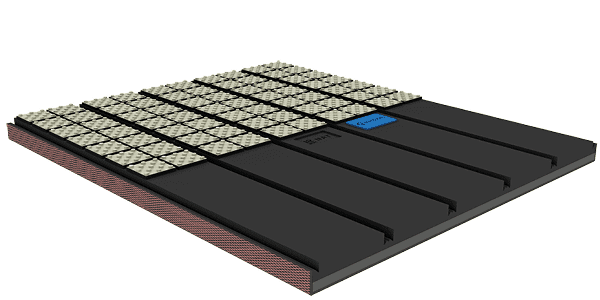

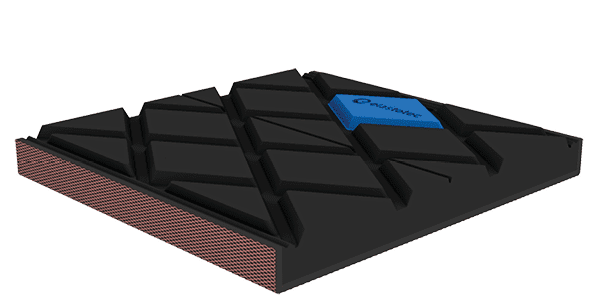

Working together with PROK, Elastotec identified the root causes and implemented a Hot Vulcanised Rubber-Backed 80% Ceramic Lagging (15mm thick with smooth tiles), developed under a high-pressure, high-temperature vulcanisation process, for maximum durability.

Since its installation in October 2024, the new lagging has delivered 12 months of trouble-free operation. There have been no breakdowns, no signs of tile loss or lagging failure, and no belt damage or tracking issues. The upgrade has provided greater efficiency and boosted confidence in long-term performance.

Key Results:

✅ New Elastotec lagging remains in service for 12+ months, with zero failures

✅ No belt damage or tracking issues

✅ Zero breakdowns since installation

✅ Reduced maintenance downtime

✅ Increased production reliability and confidence

Download the full case study and discover how Elastotec’s superior lagging design and advanced application methods are redefining pulley performance in high-spillage environment.

Case Study: How an Iron Ore Mine Solved Recurring Lagging Failures

Cutting Downtime, Protecting Belts – The Elastotec Advantage At an Iron Ore mine in Western Au

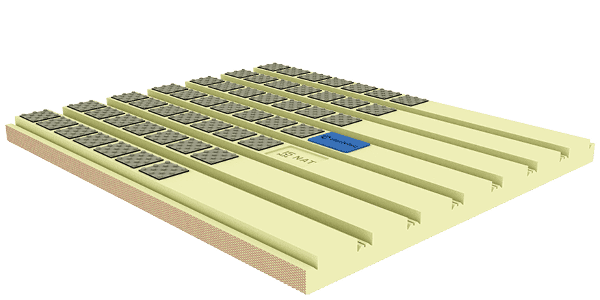

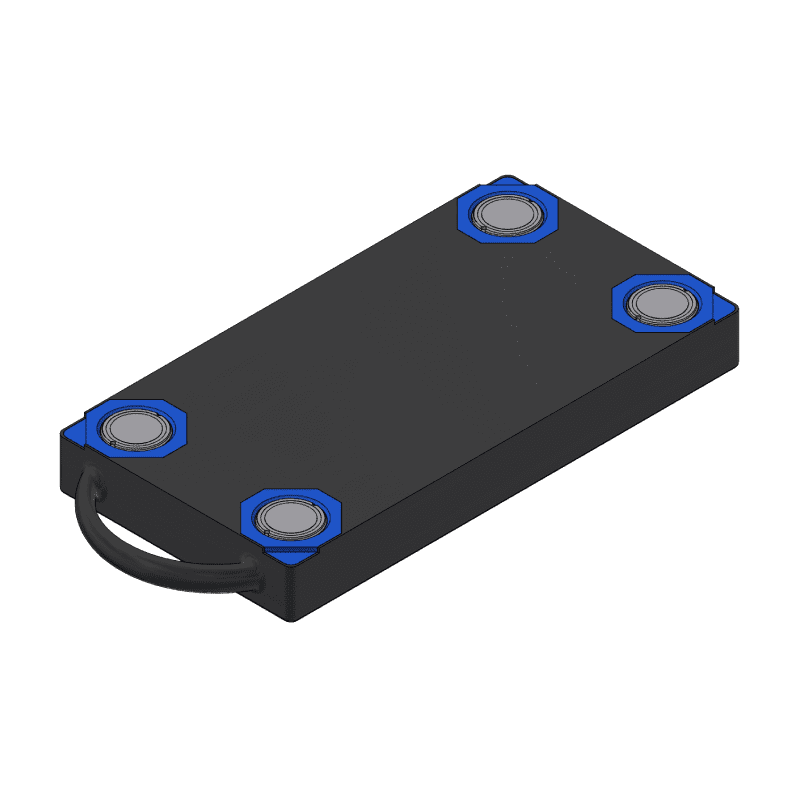

Magnefast™: Faster, Safer Wear Liner Change-Outs

Cut downtime, boost safety, and extend liner life with magnetic wear liner innovation. Extended shut

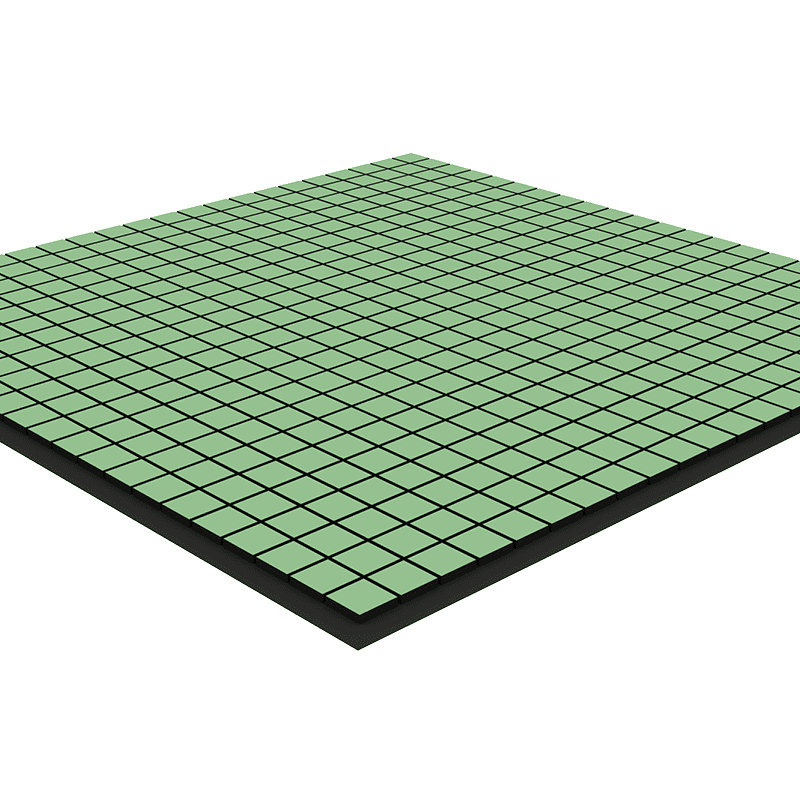

Lagging Select: What Traditional Conveyor Designs Misses

Is your conveyor truly protected from belt and lagging damage — or just barely avoiding slip? Conv