Case Study: How Lagging Select can De-Risk an Entire Mining Operation

When lagging fails, it’s not just the lagging you lose – it’s time, money, and production.

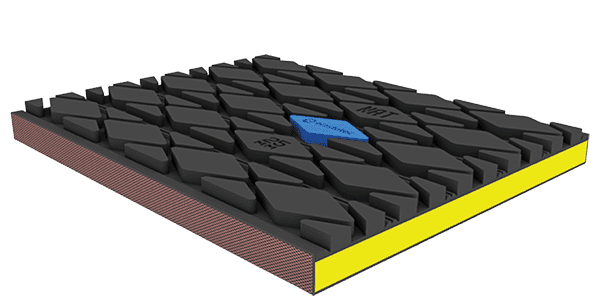

A large Australian gold mine upgraded their conveyor to increase throughput from 4,600 to 5,150 tph. The belt was upgraded, but the pulley lagging selection relied purely on historical use – no analysis was done to confirm if it could handle the higher stresses.

Within just 4 weeks, both drive pulleys failed catastrophically, causing 3 days of unplanned downtime and AUD 21 million in lost production. All from a lagging worth less than AUD 10,000.

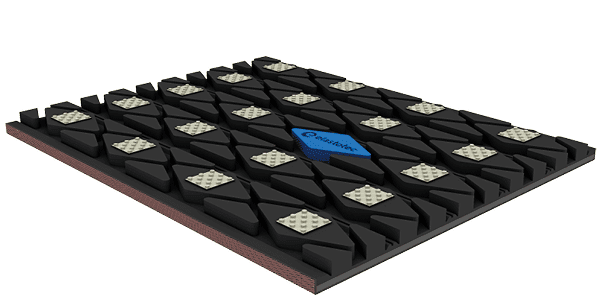

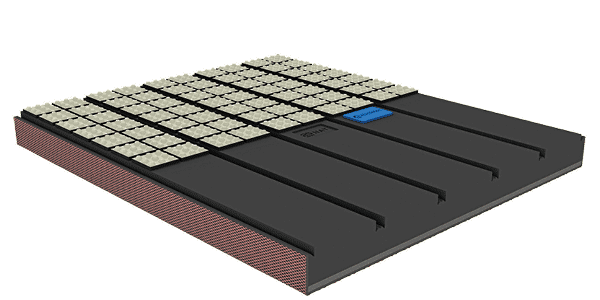

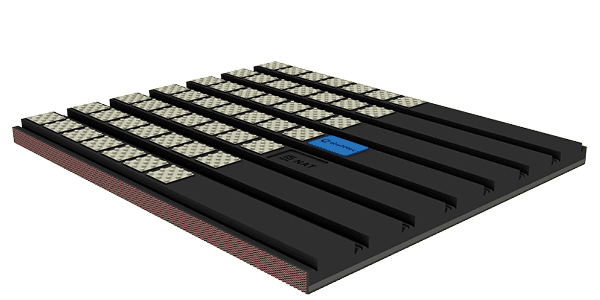

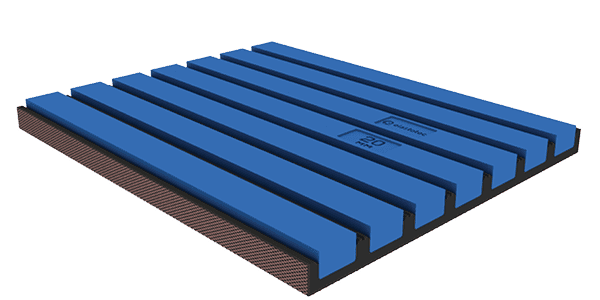

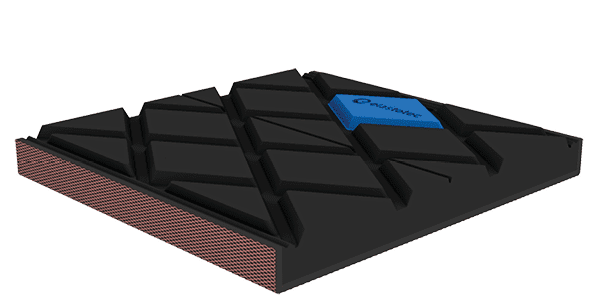

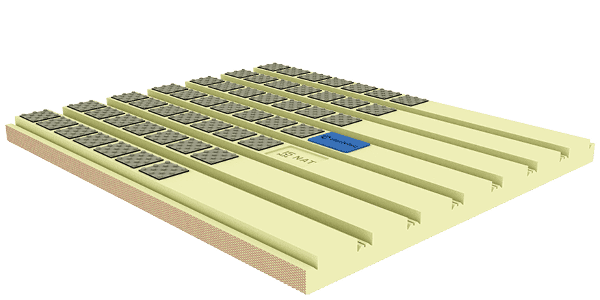

A deep investigation using Lagging Select revealed only 43% belt contact and fatigue stresses far beyond the rubber’s limits. With insights from this tool, a new Chevron lagging design was implemented – engineered for 95% contact and long-term durability. The result? Lagging life extended from 4 weeks to over 2 years.

Lagging Select is an advanced analysis tool that models the stresses between the lagging and belt. Tools like Lagging Select are transforming lagging selection from guesswork to engineered design – enabling mining operations to avoid catastrophic failures and optimise future lagging production for reliability and safety.

Lagging failure isn’t about the cost of lagging. It’s about the cost of lost production. Engineering analysis and the right lagging design matter.

This isn’t just a case study. It’s a wake-up call. Want to know what went wrong—and how it was fixed? Download the full case study now and see how data-driven design prevents million-dollar mistakes.

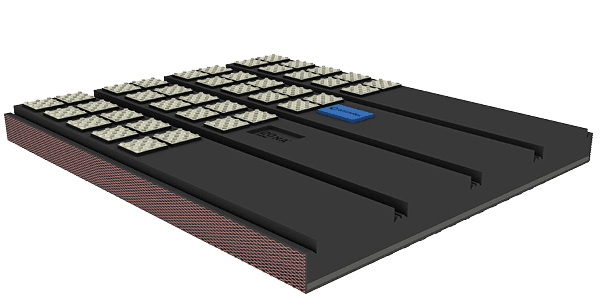

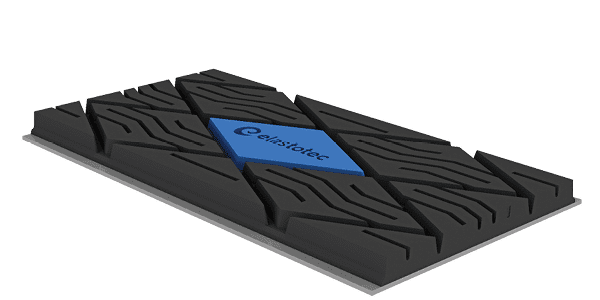

Lagging Select: What Traditional Conveyor Designs Misses

Is your conveyor truly protected from belt and lagging damage — or just barely avoiding slip? Conv

Case Study: How Lagging Select can De-Risk an Entire Mining Operation

When lagging fails, it’s not just the lagging you lose – it’s time, money, and pro

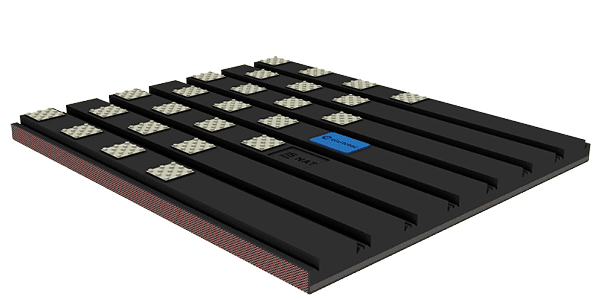

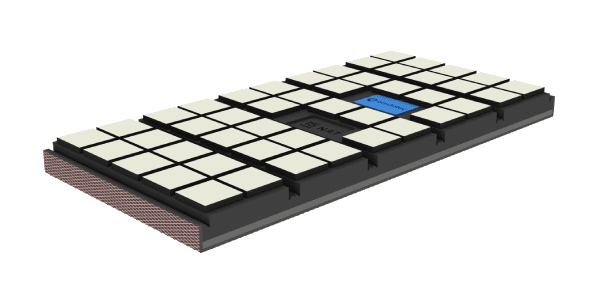

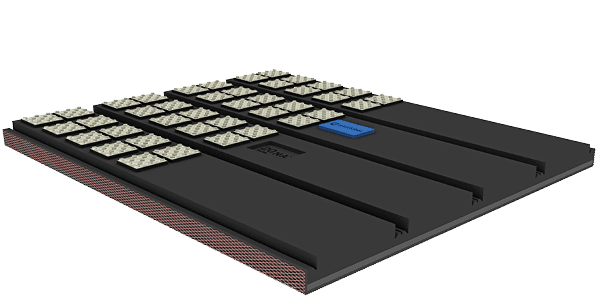

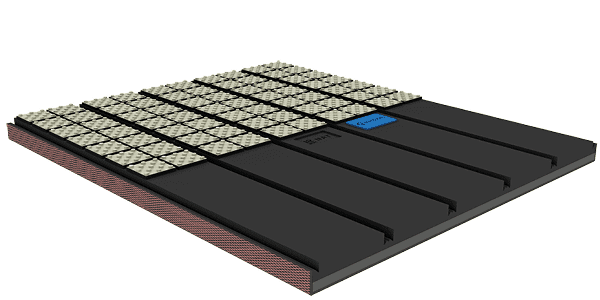

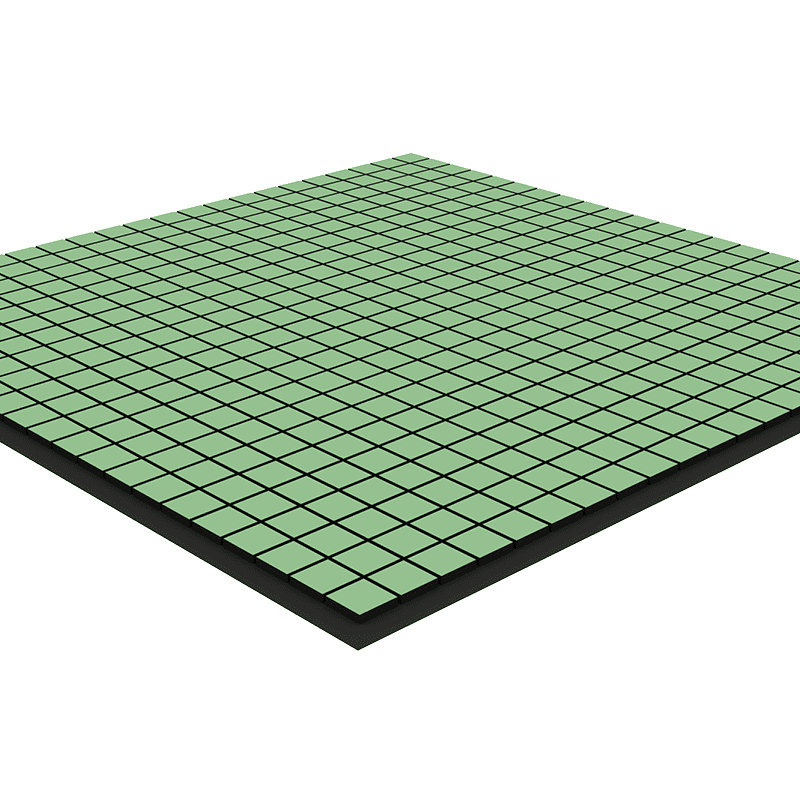

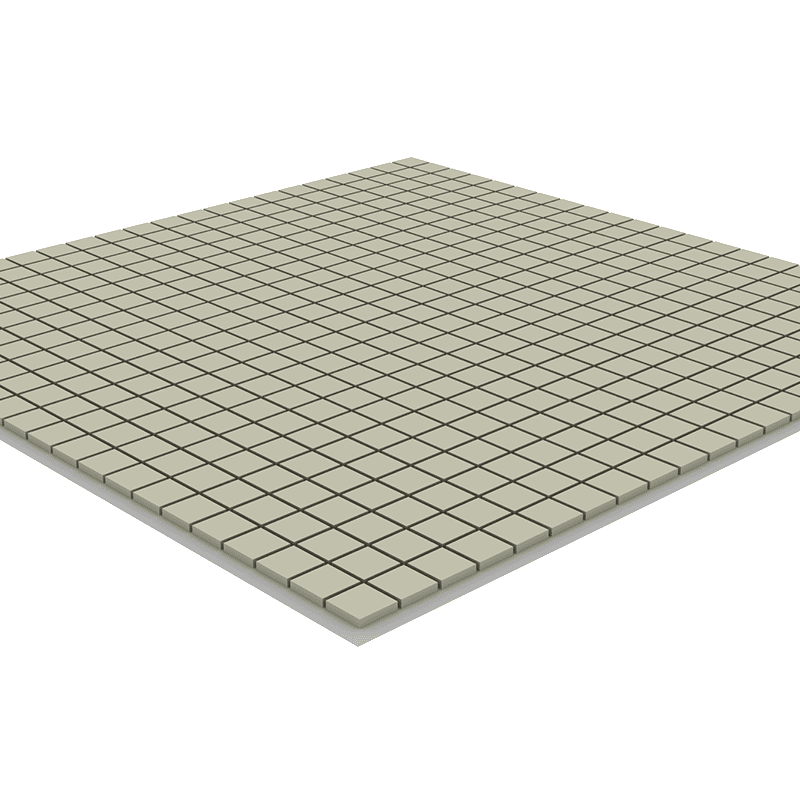

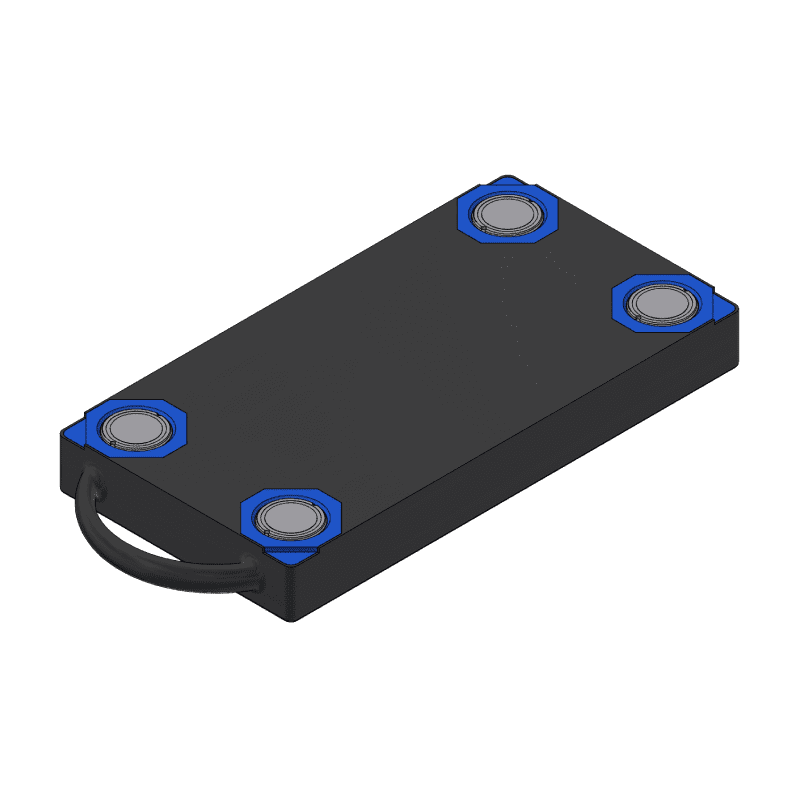

Magnefast – Polymetallic metal mine

Magnefast trial achieved 6 MONTHS service life meeting the current liner objective. The Magnefast li