Case Study: Magnefast Ceramic Liners Proven at Port Hedland

From Trial to Transformation at the World’s Largest Bulk Export Port

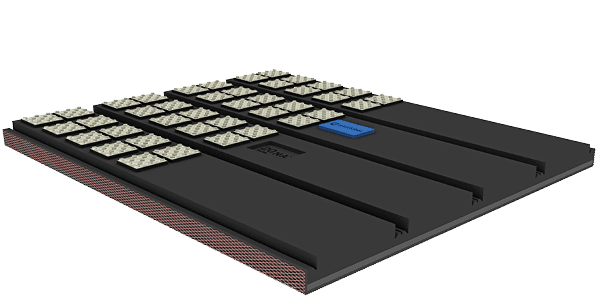

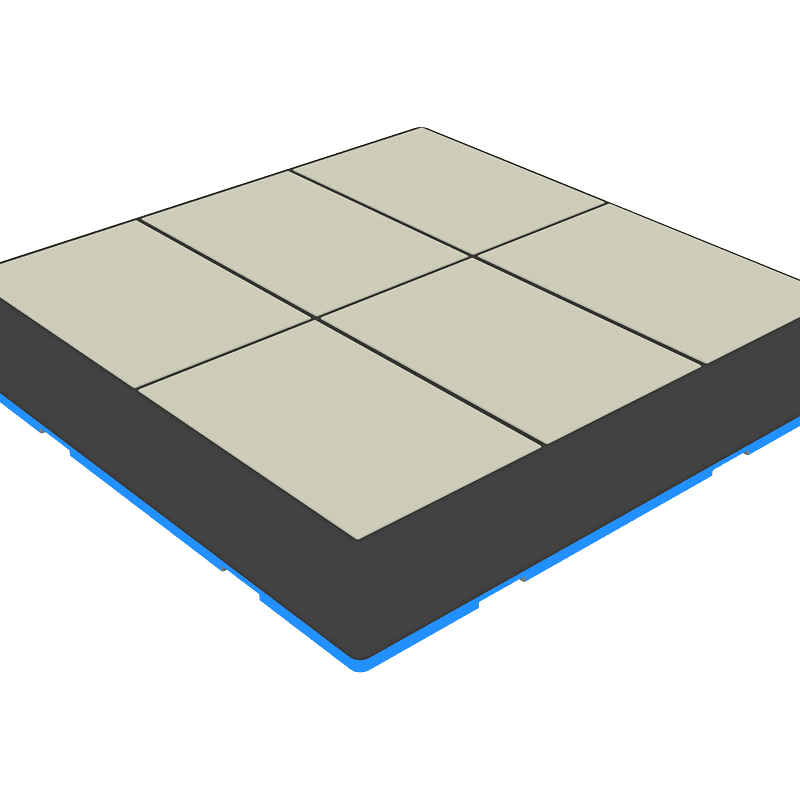

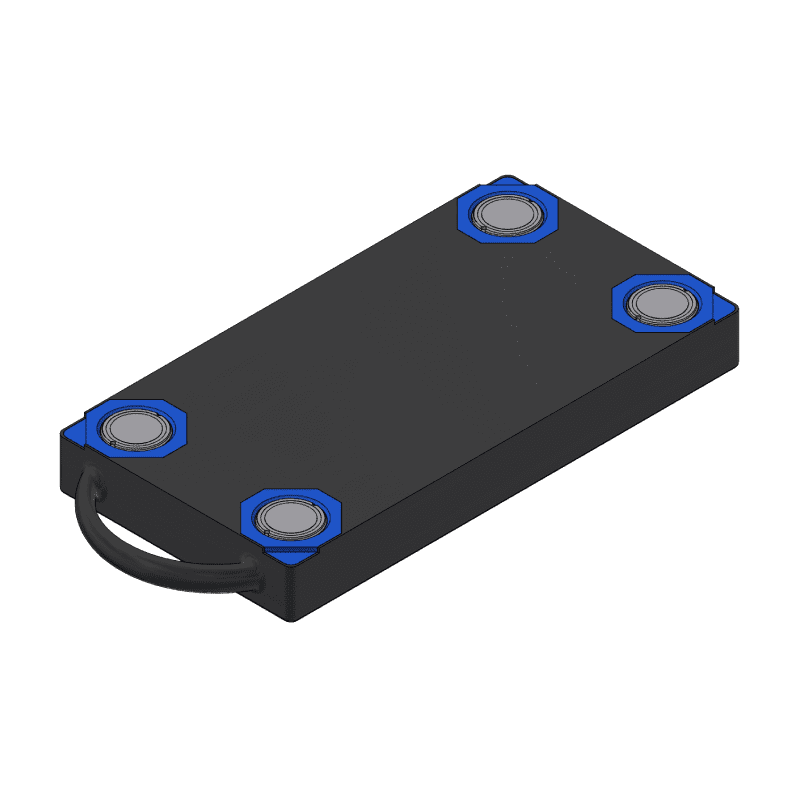

In 2019, a major export port in Port Hedland trialled the Magnefast™ Ceramic Wear Panels to solve a costly problem: Regular 10 monthly shutdowns to replace the studded Bisalloy wear liners, crane hire, and a 38 hour shut window to complete a wear liner change.

Operating 24/7 and handling iron ore, lithium and salt, they needed a solution that delivered longer service life and shorter shutdowns. In 2019, the first trial installation of Magnefast™ Ceramic Wear Panels was put in place.

Fast forward to today:

✅ The trial chute is still in operation, five years on

✅ Six chutes have now been fully converted to Magnefast™

✅ Shutdown durations reduced by 80%

✅ Liner service life increased by ~500%

The modular Magnefast™ system not only cuts downtime – it transforms planning, safety, and long-term maintenance efficiency.

Magnefast™ continues to prove its value in one of the world’s toughest environments. Want to reduce downtime and boost liner performance at your site? Download the full case study below or contact our Wear Panels team today.

Download Case Study

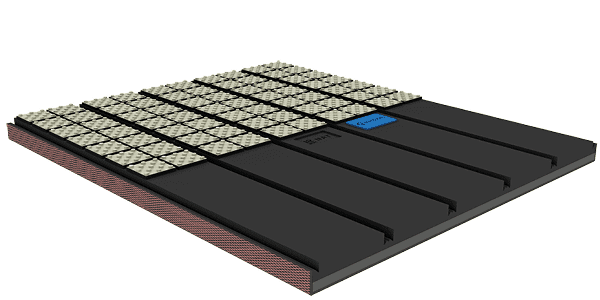

Case Study: How an Iron Ore Mine Solved Recurring Lagging Failures

Cutting Downtime, Protecting Belts – The Elastotec Advantage At an Iron Ore mine in Western Au

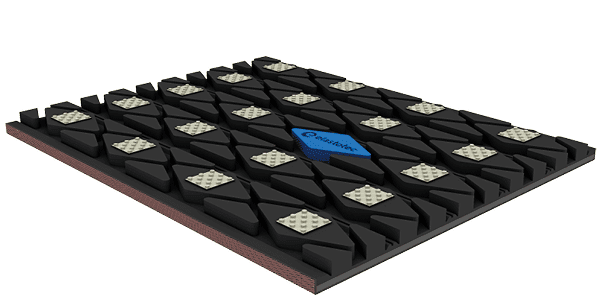

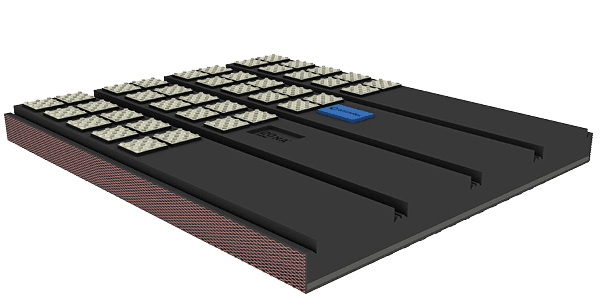

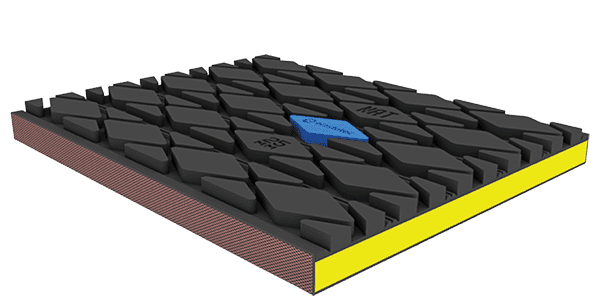

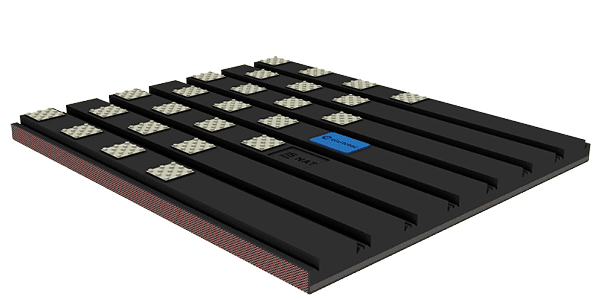

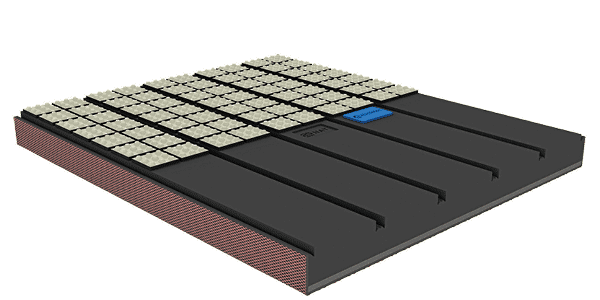

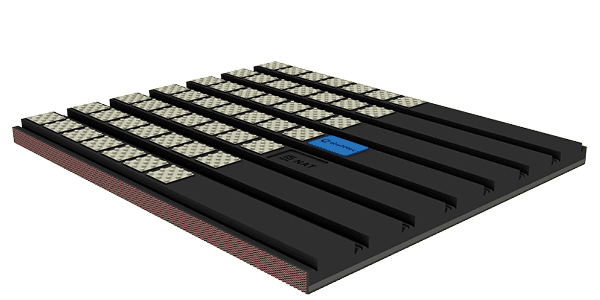

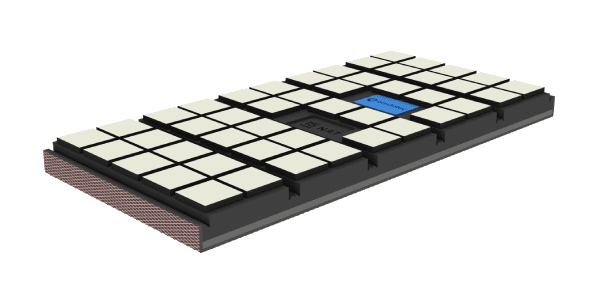

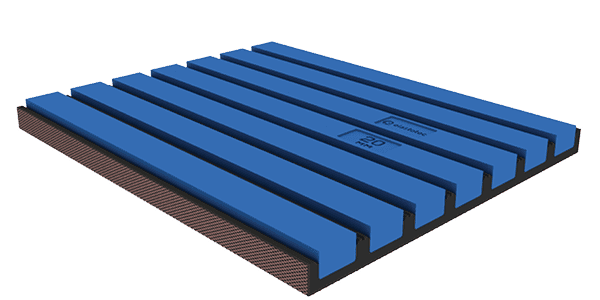

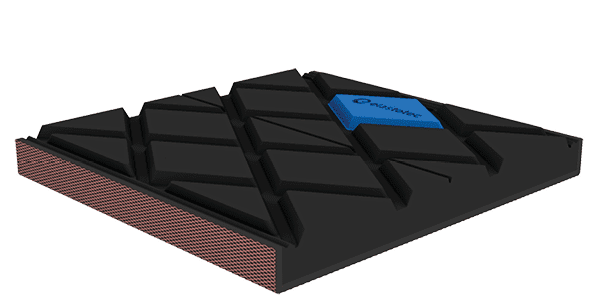

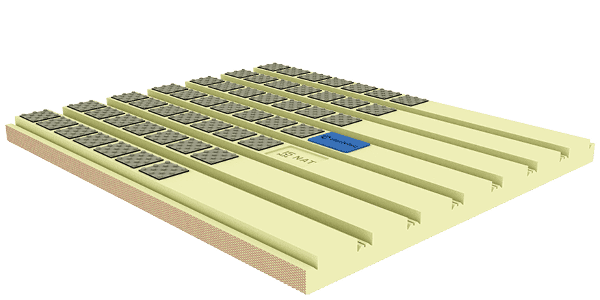

Magnefast™: Faster, Safer Wear Liner Change-Outs

Cut downtime, boost safety, and extend liner life with magnetic wear liner innovation. Extended shut

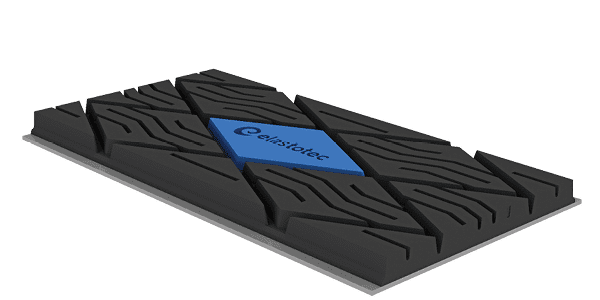

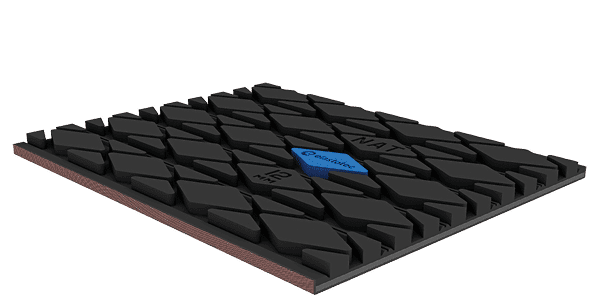

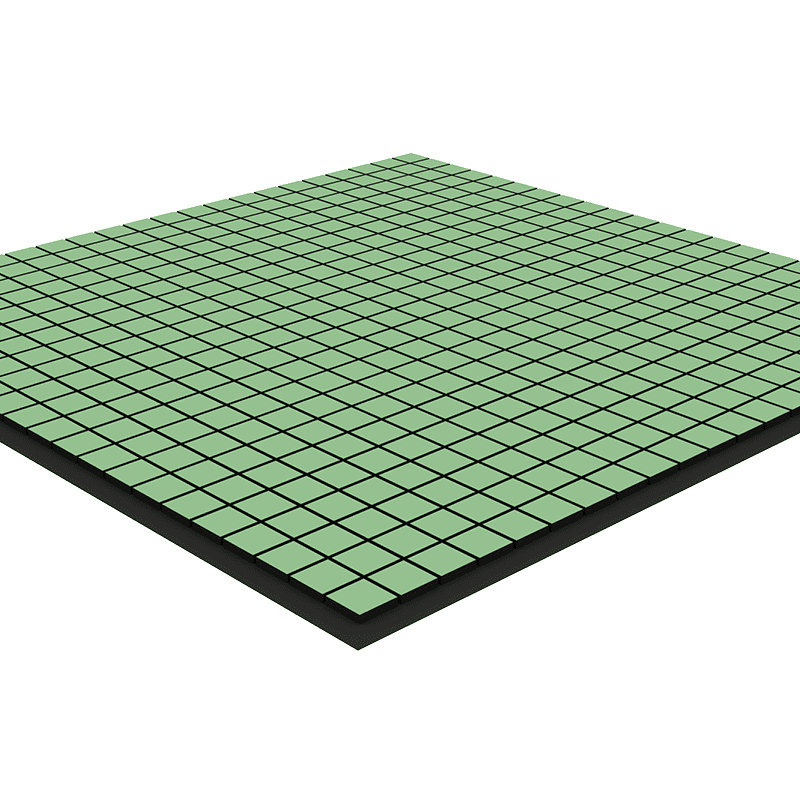

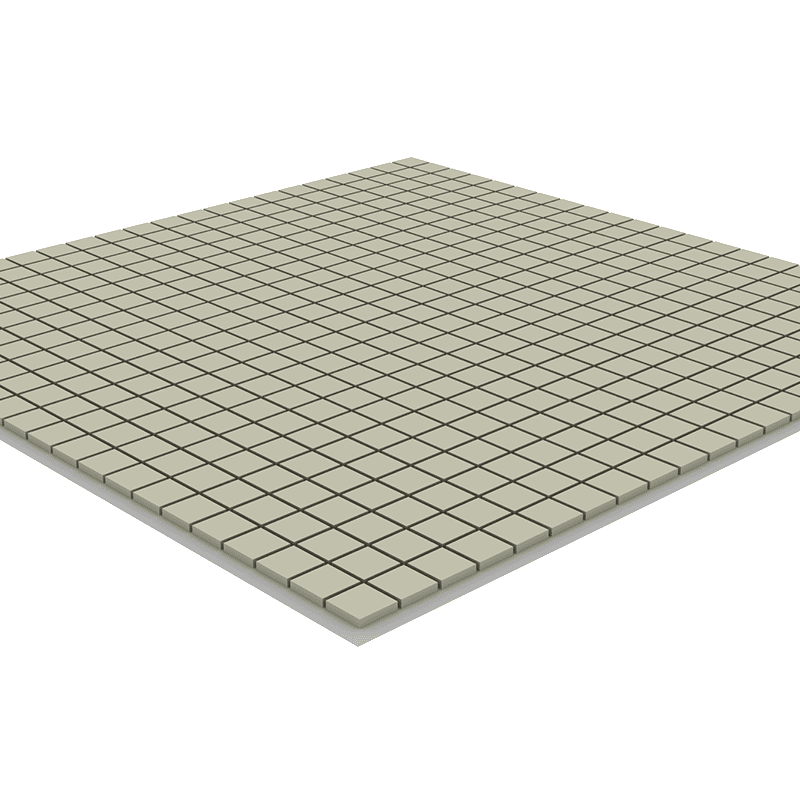

Lagging Select: What Traditional Conveyor Designs Misses

Is your conveyor truly protected from belt and lagging damage — or just barely avoiding slip? Conv