Case Study: How an Iron Ore Mine Solved Recurring Lagging Failures

Cutting Downtime, Protecting Belts – The Elastotec Advantage At an Iron Ore mine in Western Australia, recurring failures with their direct-bond ceramic lagging were costing

Cutting Downtime, Protecting Belts – The Elastotec Advantage At an Iron Ore mine in Western Australia, recurring failures with their direct-bond ceramic lagging were costing

Cut downtime, boost safety, and extend liner life with magnetic wear liner innovation. Extended shutdowns, high labour demands, and safety risks have long been challenges

Is your conveyor truly protected from belt and lagging damage — or just barely avoiding slip? Conveyor drive systems are often designed using traditional torque

From Trial to Transformation at the World’s Largest Bulk Export Port In 2019, a major export port in Port Hedland trialled the Magnefast™ Ceramic Wear

Better Lagging Selection Starts with Better Engineering Training Is your engineering team equipped to optimise conveyor design for maximum reliability and cost efficiency? Elastotec’s “Optimising

Wear Panel Solutions Engineered to Perform At Elastotec, we specialise in high-performance wear panel systems for the most demanding environments — including mining, quarrying, and

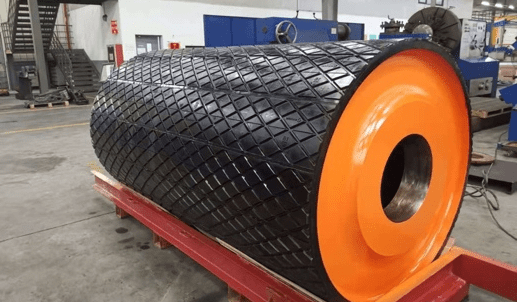

The main challenges of pulleys in contact with the carry side of the belt In conveyor systems, pulleys play a critical role in ensuring smooth

We are thrilled to share an exciting development in the field of bulk materials handling! Our recent paper, presented at the International Conference on Bulk Materials Handling (ICBMH)…

Thank you to the Peruvian mining sector. Thank you for the space to discuss your challenges. Thank you for the opportunity to redefine conveyor reliability together. So much to work together on. So much to learn together.

The Magnepatch panel can be applied over the hole on the outside of the chute with the high strength magnets holding the panel in place over the hole.

Please wait while you are redirected to the right page...