Pulley Lagging Selection and Performance Optimisation

Abstract : In belt conveying, pulley lagging is the source of necessary friction for power transfer.

Abstract : In belt conveying, pulley lagging is the source of necessary friction for power transfer.

Abstract: In bulk materials handling, areas prone to high wear are lined with wear-resistant materials that operate sacrificially and require replacement

This technical bulletin provides details on the differences between hot vulcanized lagging and cold bonded lagging, and how these differences impact the end use performance.

This technical bulletin will outline the causes of blister formation and will detail a series of simple steps that can be implemented to prevent this problem occurring.

Experts from Elastotec and the University of Newcastle explain the why it is vital to understand the coefficient of friction between the pulley lagging and the belt for optimising the design, performance, efficiency, and safety of conveyor systems.

The Elastotec aim is no pulley failures due to inadequate pulley lagging. Compare the difference between cold bonded and hot vulcanised lagging to see that hot vulcanised lagging is A GOOD BUSINESS DECISION.

Pulley lagging has historically been treated as a consumable and replaced when there’s a failure, without much further analysis other than historical experience. Mariana Ballestrin from Elastotec explains why making solutions based on historical experience is a simple guess.

Elastotec, a specialist in pulley lagging, has partnered with TUNRA Bulk Solids and the University of Newcastle to better understand how close to the fatigue limit lagging is operating.

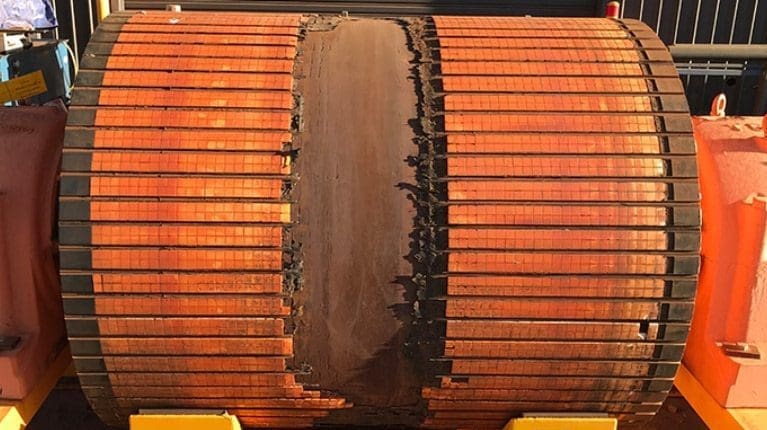

As conveyors have increased in capacity, the amount of power being transmitted though the rubber lagging has also increased. As a result, we are now seeing failures of rubber lagging due to delamination of drive pulleys and high-tension bend pulleys.

Lagging Selection is key to obtaining the best possible lagging performance and a recent visit to a pulley refurbishment facility emphasised this with three pulleys on the floor – two with cold bonded ceramic lagging and one with hot vulcanised ceramic lagging.

Please wait while you are redirected to the right page...