A deeper understanding of conveyer pulley friction

Experts from the University of Newcastle and Elastotec investigate the emerging issues around pulley friction, the complexity of the issue, and the failures that may result.

Experts from the University of Newcastle and Elastotec investigate the emerging issues around pulley friction, the complexity of the issue, and the failures that may result.

Lagging can be of good quality and application can be correct, but lagging can still fail and does. Everything seems right but the lagging still doesn’t perform to expectations. So why does this happen? It’s because the lagging selection is not right for the application.

Ceramic lagging is widely used in applications that require increased levels of grip and long service life.

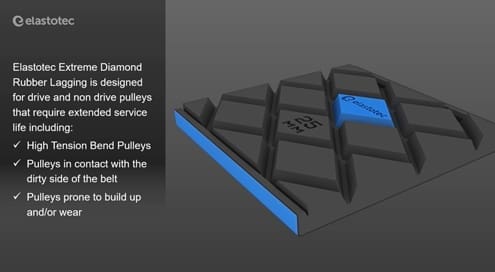

Elastotec extreme diamond rubber lagging is designed for drive and non drive pulleys that require extended service life.

At Elastotec, we engineer lagging solutions that keep conveyors running. Here are some causes of lagging failure.

Elastotec Direct Bond Ceramic Lagging – application system designed to improve adhesion consistency, reduce lead times, reduce glue wastage and labour time.

Hot Vulcanised lagging application involves the chemical cross-linking of five reactive layers during the autoclave curing process. To achieve the desired 100% rubber tear adhesion all five layers must crosslink at the same time. Occasionally conditions can be created in the autoclave that prevent this happening, and result in non-uniform adhesion around the pulley circumference. This bulletin explains how these conditions occur and what needs to be done to eliminate this problem.

Spare pulleys are held so that in the event that an operational pulley requires replacement this can be done quickly and efficiently at the timing dictated by the mine maintenance personnel. The reason for changing a pulley broadly falls into two categories:

Please wait while you are redirected to the right page...