Case Study: Magnefast Ceramic Liners Proven at Port Hedland

From Trial to Transformation at the World’s Largest Bulk Export Port In 2019, a major export port in Port Hedland trialled the Magnefast™ Ceramic Wear

From Trial to Transformation at the World’s Largest Bulk Export Port In 2019, a major export port in Port Hedland trialled the Magnefast™ Ceramic Wear

Magnefast trial achieved 6 MONTHS service life meeting the current liner objective. The Magnefast liners showed 7 mm of wear in a 50 mm thick ceramic so panels have not been replaced and are expected to eliminate a number of liner…

80% less replacement time with Magnefast. Increase conveyor operating time. Do more during shutdown. Save on labour time. No crane needed.

As part of a major production upgrade at a large gold mine Carters Engineering was asked to produce a new slurry box for the ore treatment plant. The slurry box was to be located in a position with difficult access making removal/replacement difficult.

This quarry located in the south-eastern region of New South Wales is a hard rock quarry that can produce up to 1.5 million tonnes per annum of quarry products.

Located in southwest of Sydney this hard rock quarry can produce up to 5 million tonnes per annum of products (ballast, aggregate, manufactured sand and road base).

Keep your staff safe with no external scaffolding, no electrical, hydraulic or pneumatic tools – no drop from heights risks or stud cutting.

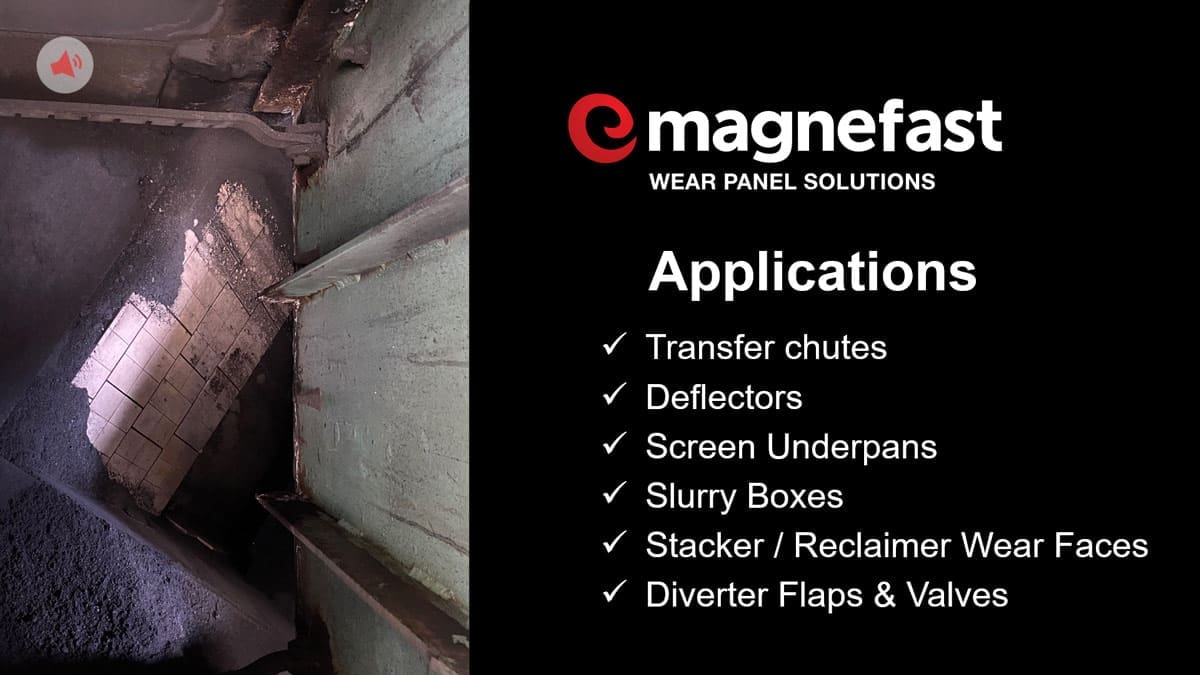

Magnefast wear panel solutions: proven performance for large Copper & Coal Mines, Power Station, Sand & Gravel Quarry, Iron Ore Export Port.

No scaffold/studs or tools needed to install, great for locations with difficult access, no hole-stud alignment needed, no panel gaps.

Magnefast is a patented single sided attachment system for wear panels that uses high strength neodymium magnets to hold the panels in place.

Please wait while you are redirected to the right page...