Case Study: How an Iron Ore Mine Solved Recurring Lagging Failures

Cutting Downtime, Protecting Belts – The Elastotec Advantage At an Iron Ore mine in Western Australia, recurring failures with their direct-bond ceramic lagging were costing

Cutting Downtime, Protecting Belts – The Elastotec Advantage At an Iron Ore mine in Western Australia, recurring failures with their direct-bond ceramic lagging were costing

Cut downtime, boost safety, and extend liner life with magnetic wear liner innovation. Extended shutdowns, high labour demands, and safety risks have long been challenges

Upgrade to Magnefast™ Wear Liners – Faster, Safer, and Leak-Free. Studded liners don’t just slow down your maintenance. They create daily headaches: Frequent, time-consuming changeouts

Magnefast trial achieved 6 MONTHS service life meeting the current liner objective. The Magnefast liners showed 7 mm of wear in a 50 mm thick ceramic so panels have not been replaced and are expected to eliminate a number of liner…

80% less replacement time with Magnefast. Increase conveyor operating time. Do more during shutdown. Save on labour time. No crane needed.

As part of a major production upgrade at a large gold mine Carters Engineering was asked to produce a new slurry box for the ore treatment plant. The slurry box was to be located in a position with difficult access making removal/replacement difficult.

This quarry located in the south-eastern region of New South Wales is a hard rock quarry that can produce up to 1.5 million tonnes per annum of quarry products.

Located in southwest of Sydney this hard rock quarry can produce up to 5 million tonnes per annum of products (ballast, aggregate, manufactured sand and road base).

Keep your staff safe with no external scaffolding, no electrical, hydraulic or pneumatic tools – no drop from heights risks or stud cutting.

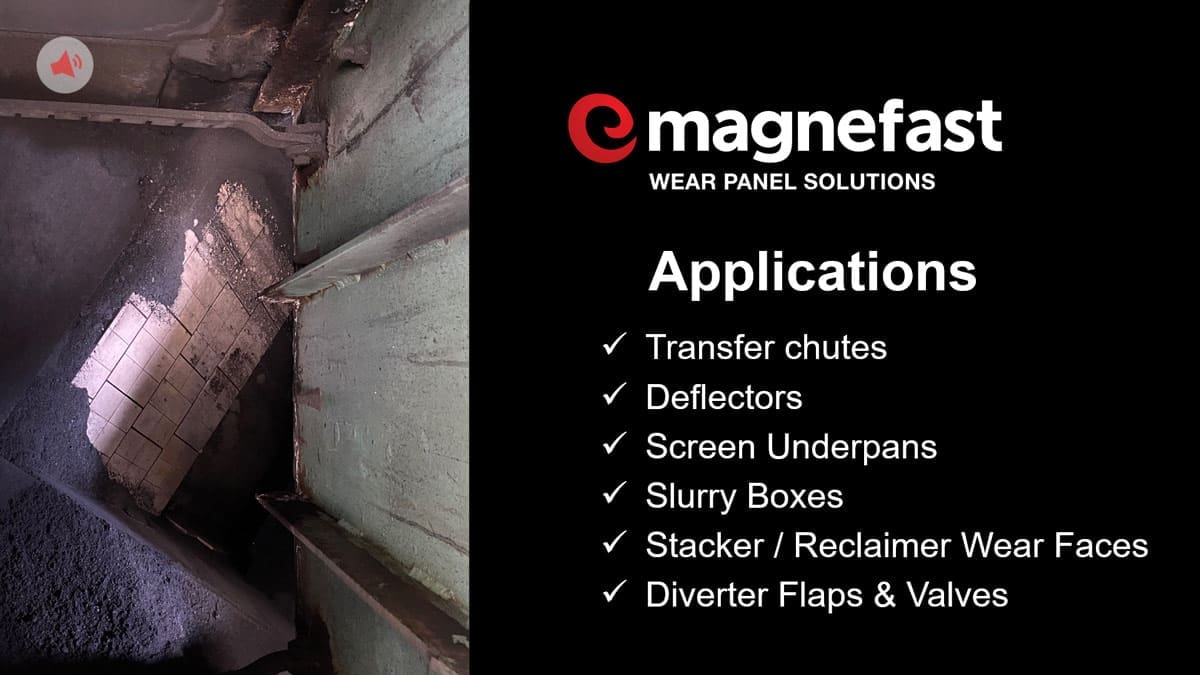

Magnefast wear panel solutions: proven performance for large Copper & Coal Mines, Power Station, Sand & Gravel Quarry, Iron Ore Export Port.

Please wait while you are redirected to the right page...