Lagging Select: What Traditional Conveyor Designs Misses

Is your conveyor truly protected from belt and lagging damage — or just barely avoiding slip?

Conveyor drive systems are often designed using traditional torque transfer calculations like Euler’s equation, supported by CEMA guidelines. These methods help prevent full slip between belt and pulley.

But what they don’t show is the localised slip that silently damages pulley lagging and belt covers — even when your design “checks out.”

Euler ≠ Protection from Wear

The Euler method focuses only on power transmission — how much torque the pulley can transfer without full slip. It doesn’t consider:

- Shear and normal stress at the lagging-belt interface

- Localised slip that leads to premature wear

- Fatigue failure of lagging and belt splices

What we need is a more complete view:

- Analysis of stress propagation across the contact arc

- Understanding of how friction varies with pressure, slip speed & displacement

- Testing to define variant coefficients of friction — not just conservative estimates

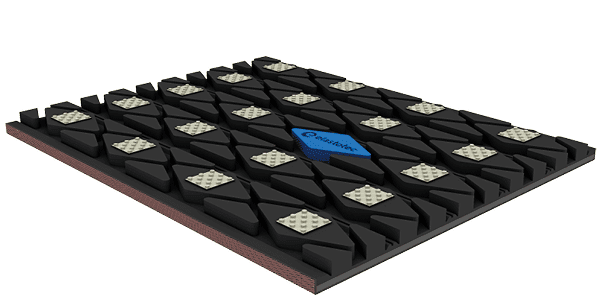

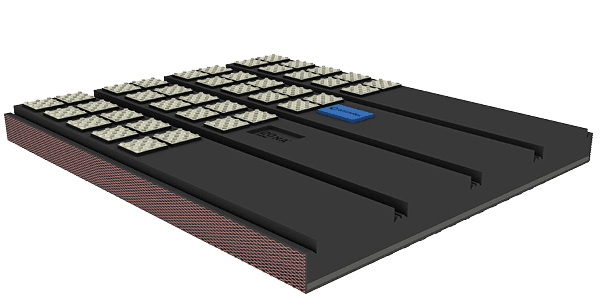

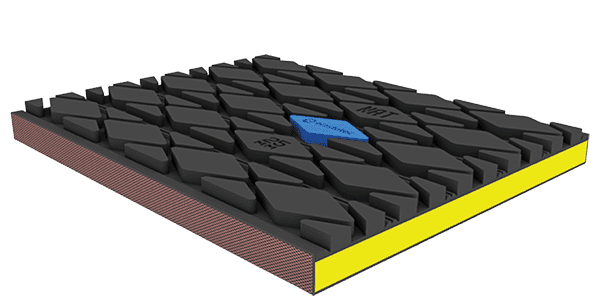

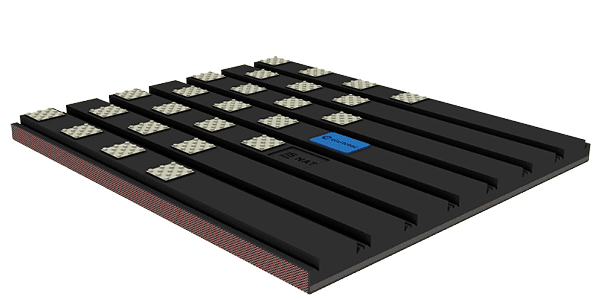

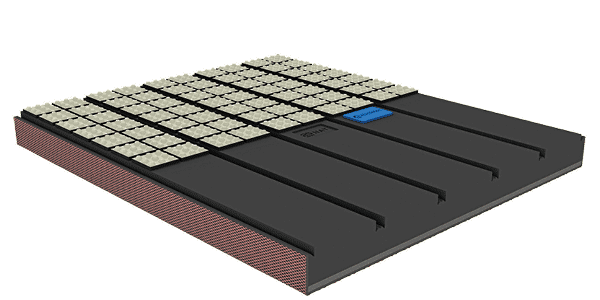

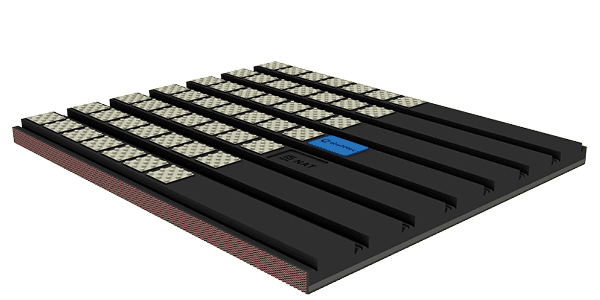

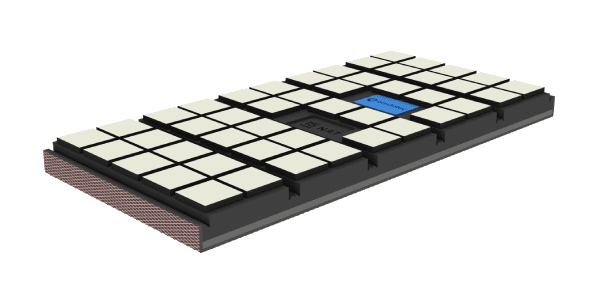

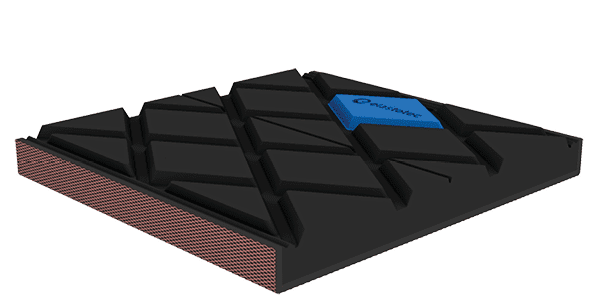

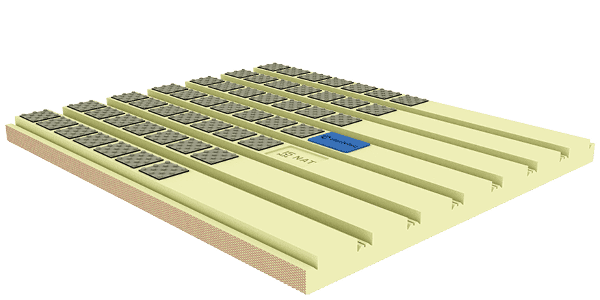

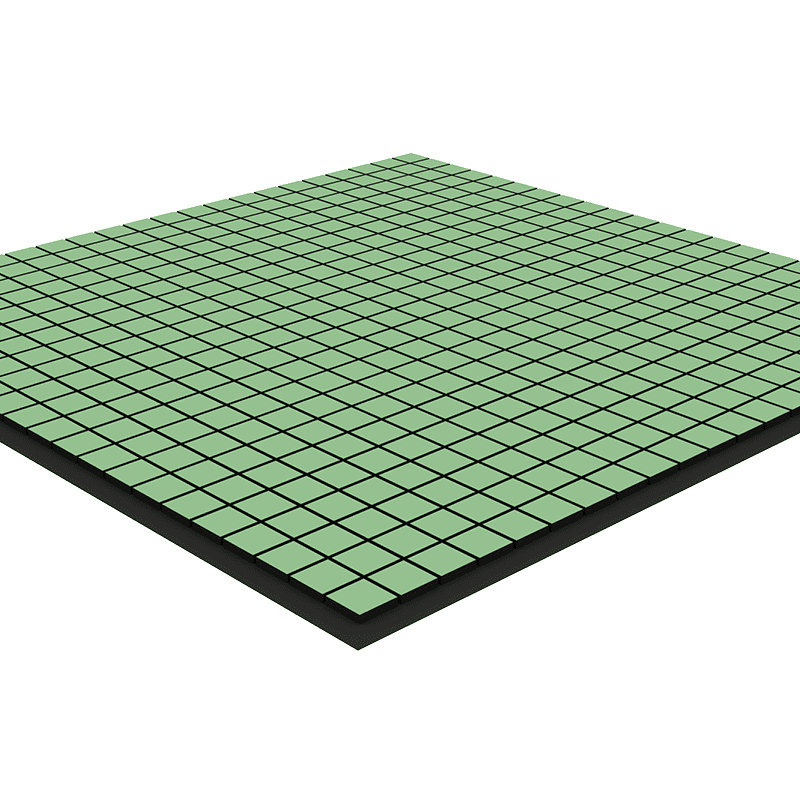

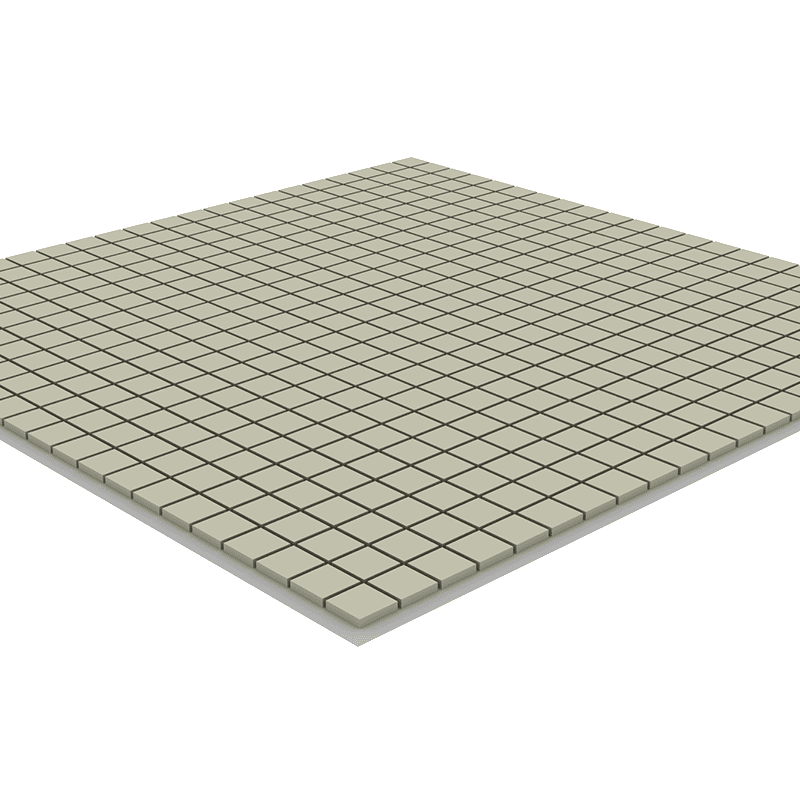

This is where Lagging Select makes a difference. Lagging Select provides advanced modelling to analyse the cyclic stress distribution within the lagging and belt — helping identify:

✅ Areas at risk of localized slip

✅ Zones of excessive fatigue loading

✅ Whether friction is sufficient to maintain contact without damage

Even when a design passes traditional calculations, Lagging Select can reveal issues like 47° of slip or 106% fatigue stress — insights that can’t be seen through Euler alone.

It’s time to go beyond simple friction numbers and design with service life in mind, not just torque.

Lagging Select sees what Euler can’t — model cyclic stress, friction behaviour, and fatigue risks — with confidence. Don’t guess, do a stress test.

Download the Lagging Select case study below or contact our Pulley Lagging team to learn more.

Download Case Study

Case Study: How an Iron Ore Mine Solved Recurring Lagging Failures

Cutting Downtime, Protecting Belts – The Elastotec Advantage At an Iron Ore mine in Western Au

Magnefast™: Faster, Safer Wear Liner Change-Outs

Cut downtime, boost safety, and extend liner life with magnetic wear liner innovation. Extended shut

Lagging Select: What Traditional Conveyor Designs Misses

Is your conveyor truly protected from belt and lagging damage — or just barely avoiding slip? Conv