Improvements in Wear Liner technology

Elastotec Unveils the recent Improvements in Wear Liner technology at ICBMH Conference

We are thrilled to share an exciting development in the field of bulk materials handling! Our recent paper, presented at the International Conference on Bulk Materials Handling (ICBMH), introduces a groundbreaking approach that promises to reshape wear protection strategies for critical equipment used across industries such as mining.

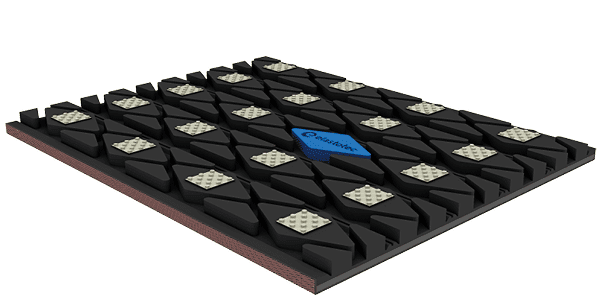

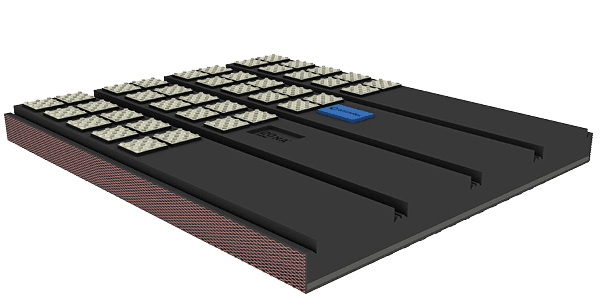

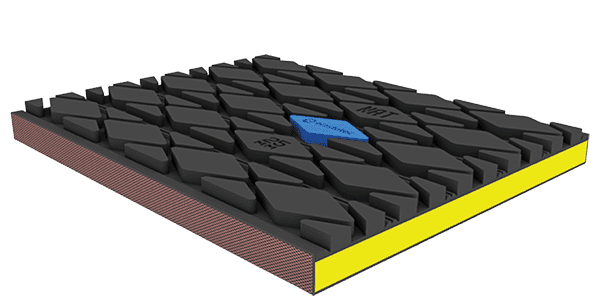

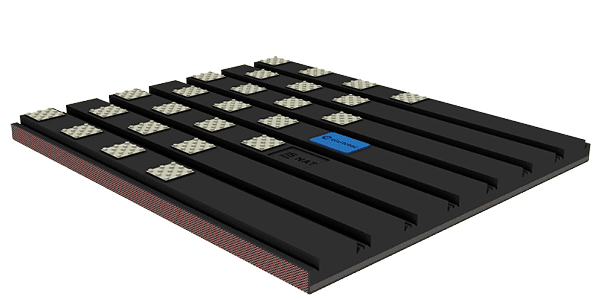

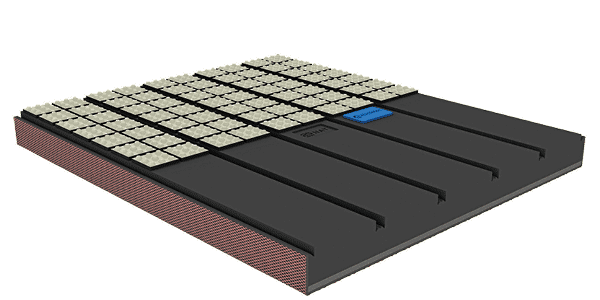

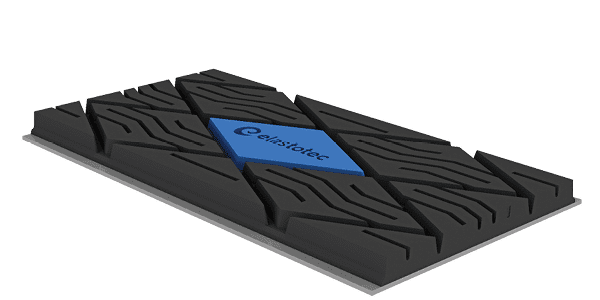

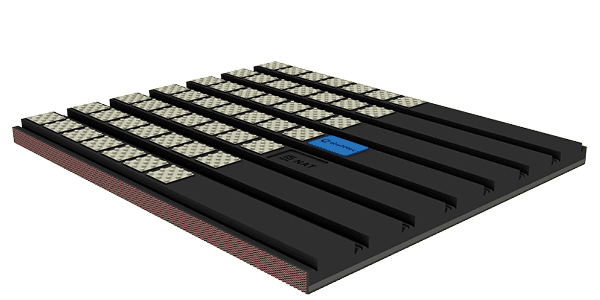

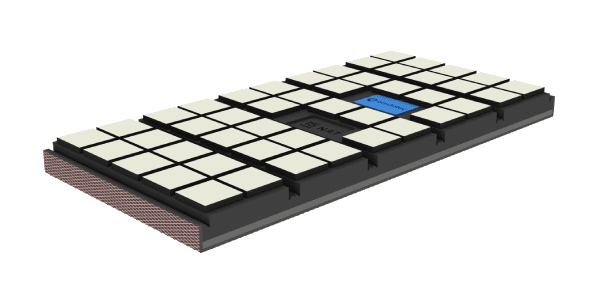

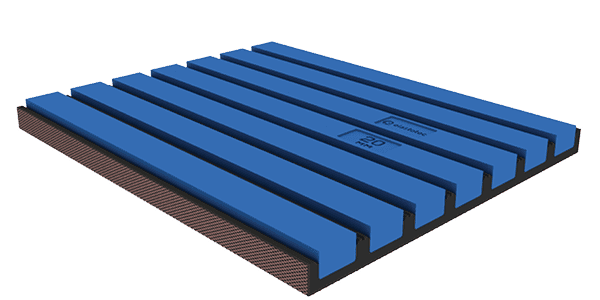

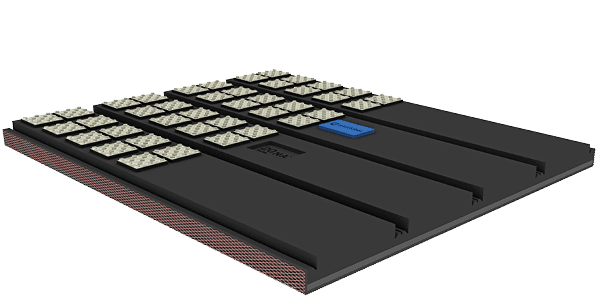

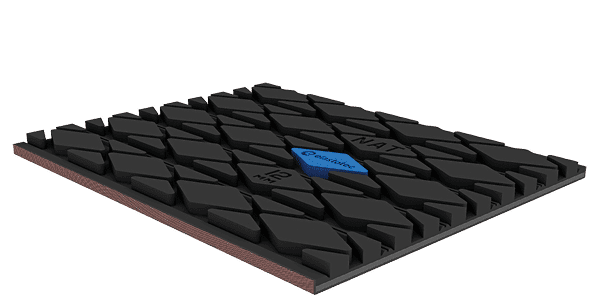

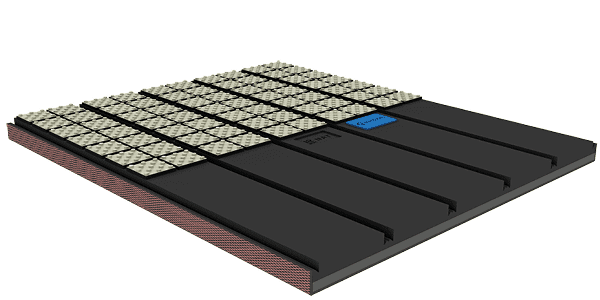

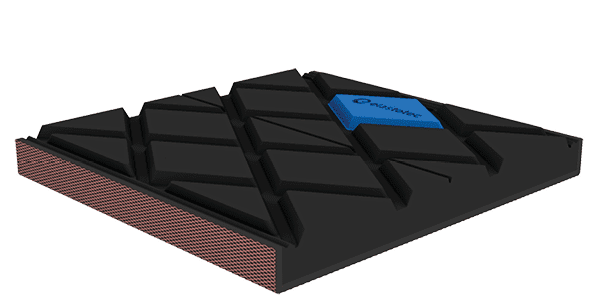

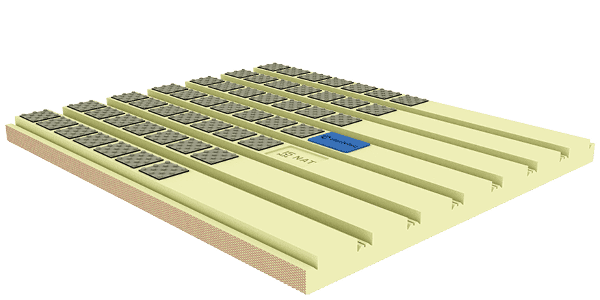

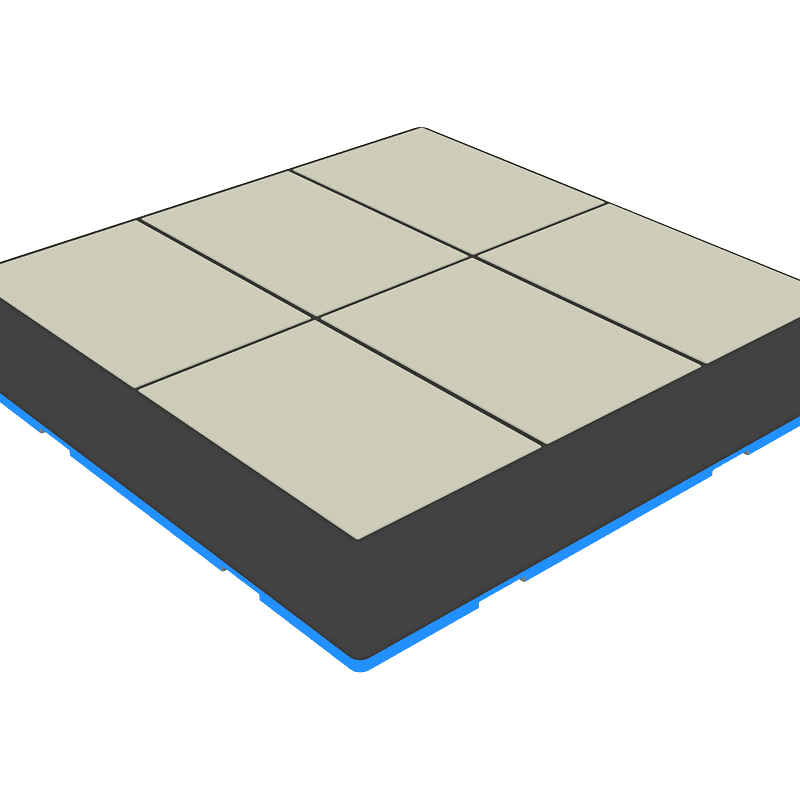

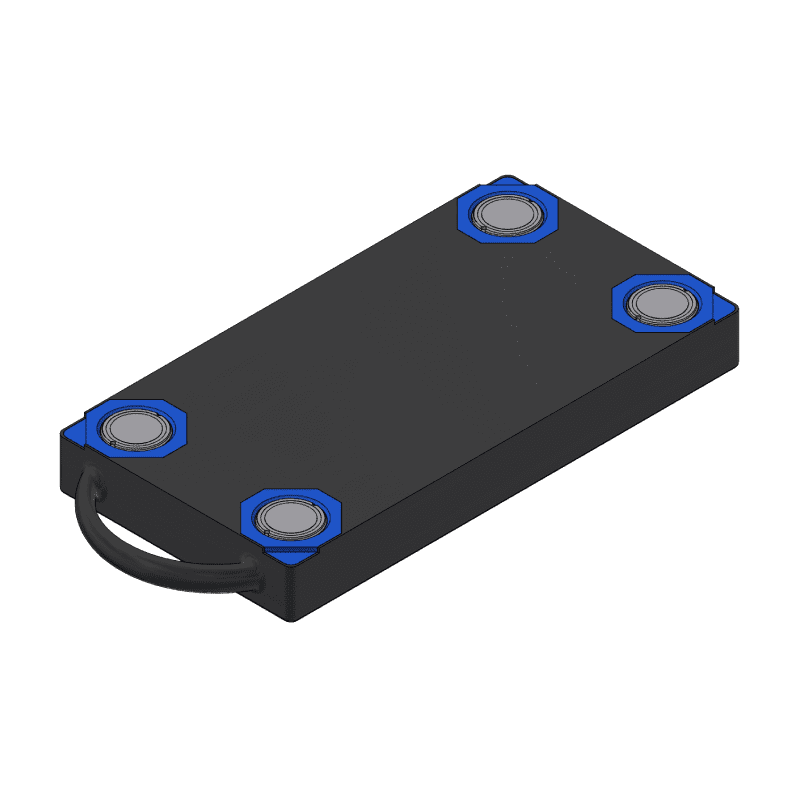

At the heart of our presentation is an innovative method of wear liner attachment based on high-strength magnets. This transformative solution addresses the challenges posed by traditional wear-resistant materials and attachment techniques. By significantly reducing equipment downtime, labor requirements, and safety risks, our magnetic attachment method has the potential to revolutionize the way we approach wear protection in bulk materials handling.

The paper provides a comprehensive exploration of the engineering, testing, and successful field trials that underline the effectiveness of our high-strength magnet approach. Our solution’s capacity to withstand a wide range of climatic conditions, coupled with its practical implementation insights, makes it a promising avenue for enhancing operational efficiency and reducing costs in global mining and related operations.

We invite you to delve into the details of our presentation and discover how this innovation has the power to transform the landscape of bulk materials handling. Stay tuned as we continue to share updates and insights contributing to a more efficient and sustainable future for industries reliant on bulk materials handling.

Case Study: How an Iron Ore Mine Solved Recurring Lagging Failures

Cutting Downtime, Protecting Belts – The Elastotec Advantage At an Iron Ore mine in Western Au

Magnefast™: Faster, Safer Wear Liner Change-Outs

Cut downtime, boost safety, and extend liner life with magnetic wear liner innovation. Extended shut

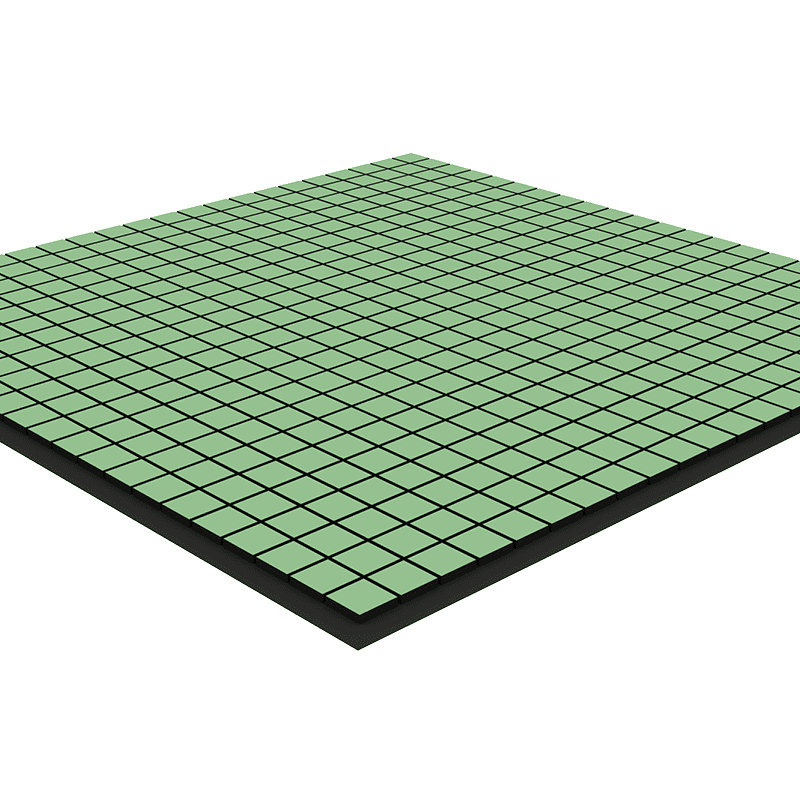

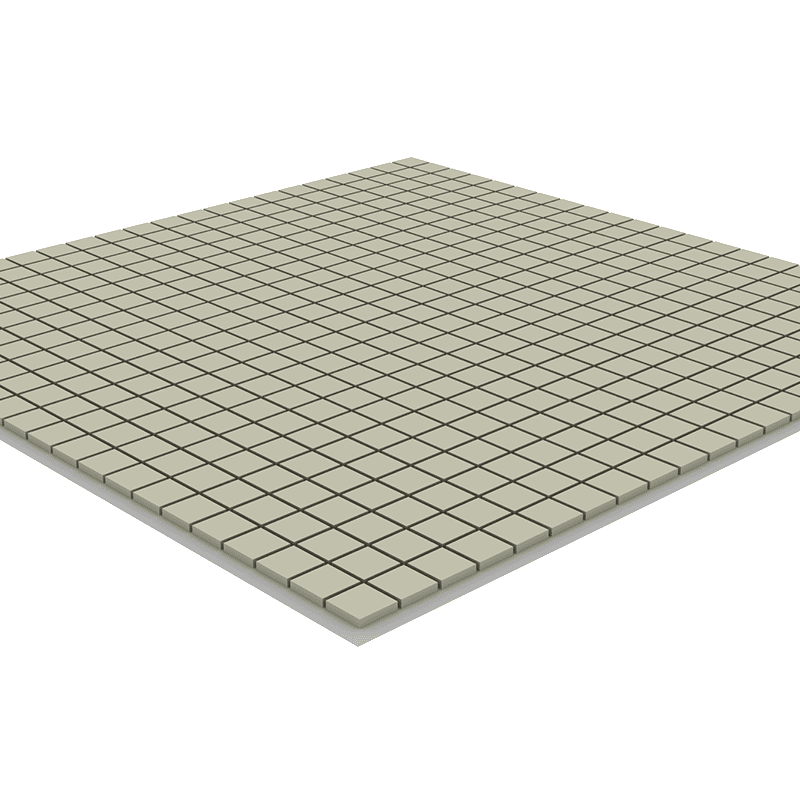

Lagging Select: What Traditional Conveyor Designs Misses

Is your conveyor truly protected from belt and lagging damage — or just barely avoiding slip? Conv