Technical Bulletin: Magnefast™ Wear Liners in Slurry Boxes & Wet Chutes

Upgrade to Magnefast™ Wear Liners – Faster, Safer, and Leak-Free.

Studded liners don’t just slow down your maintenance. They create daily headaches:

- Frequent, time-consuming changeouts

- Difficult removal and reinstallation

- Leakage through stud holes leading to corrosion

- Increased OH&S risks from hot work and heavy tools

If your team is dealing with leakage, corrosion, and extended downtime, it’s time for a better solution.

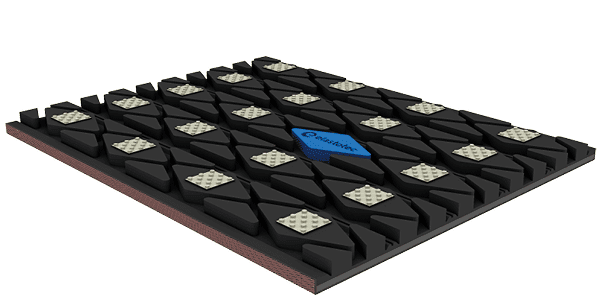

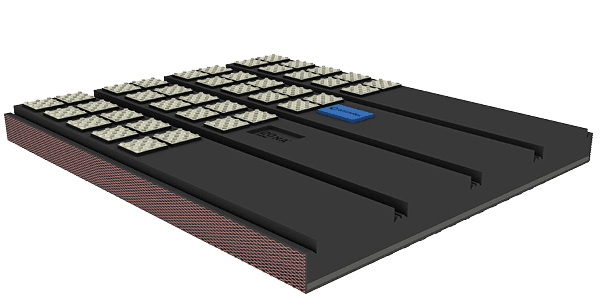

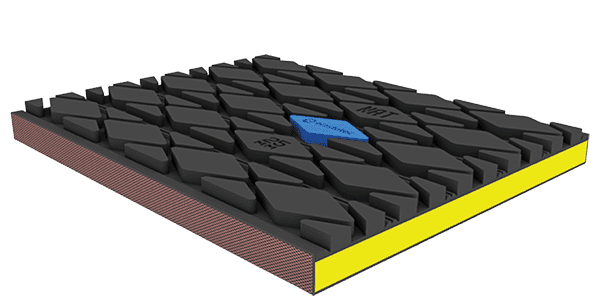

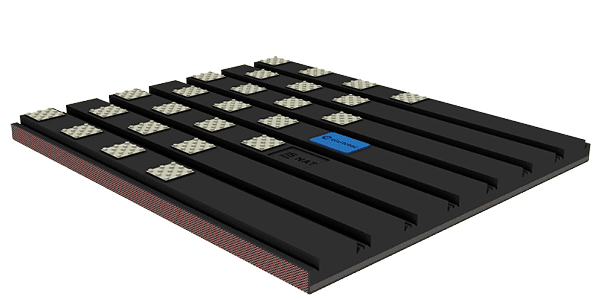

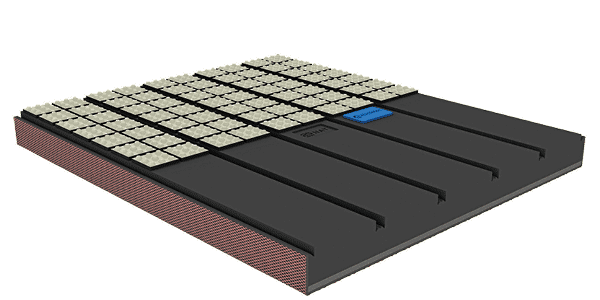

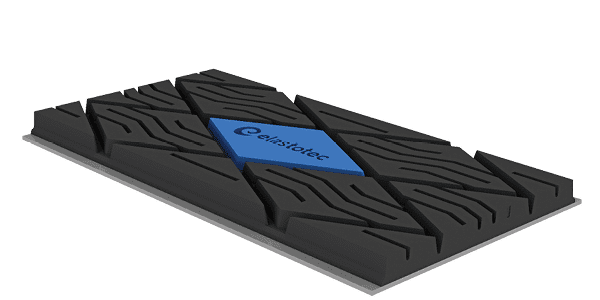

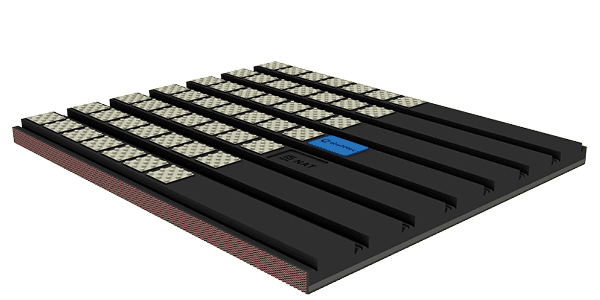

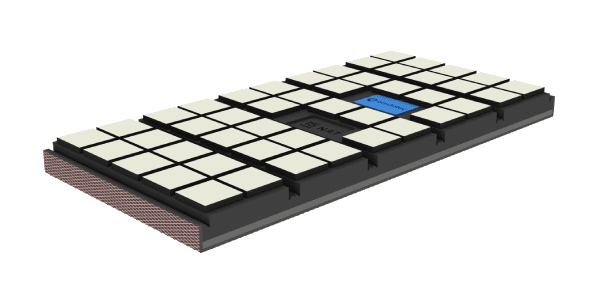

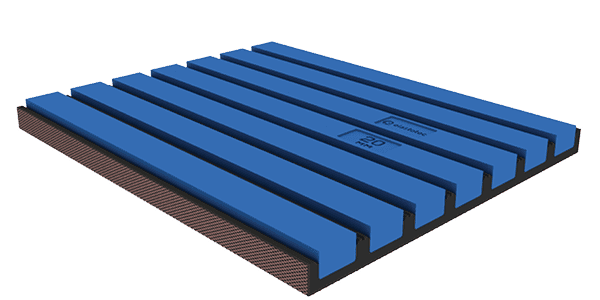

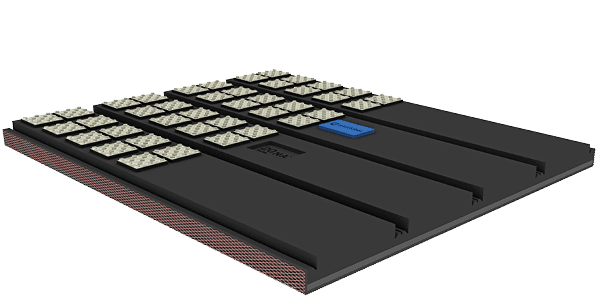

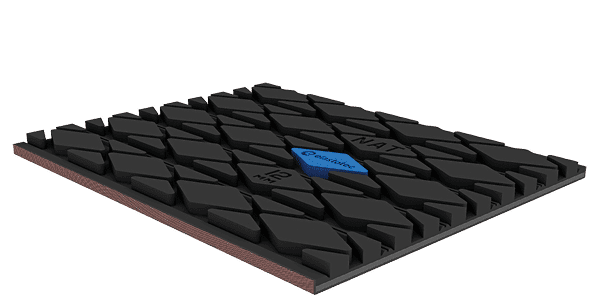

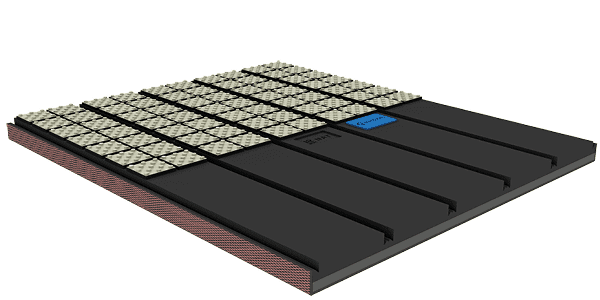

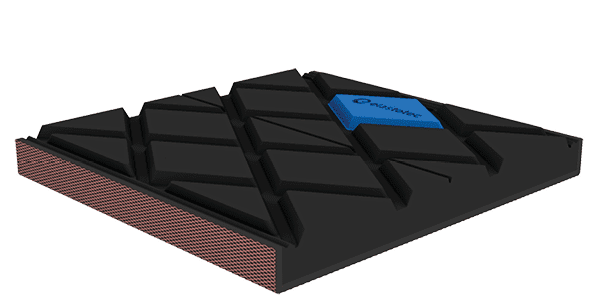

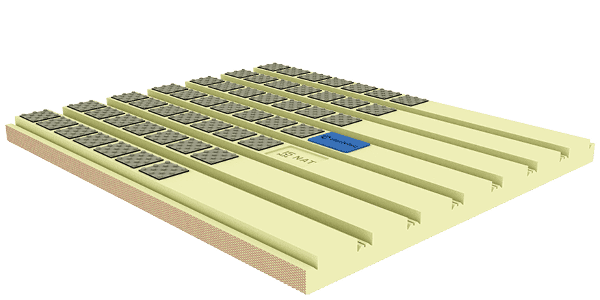

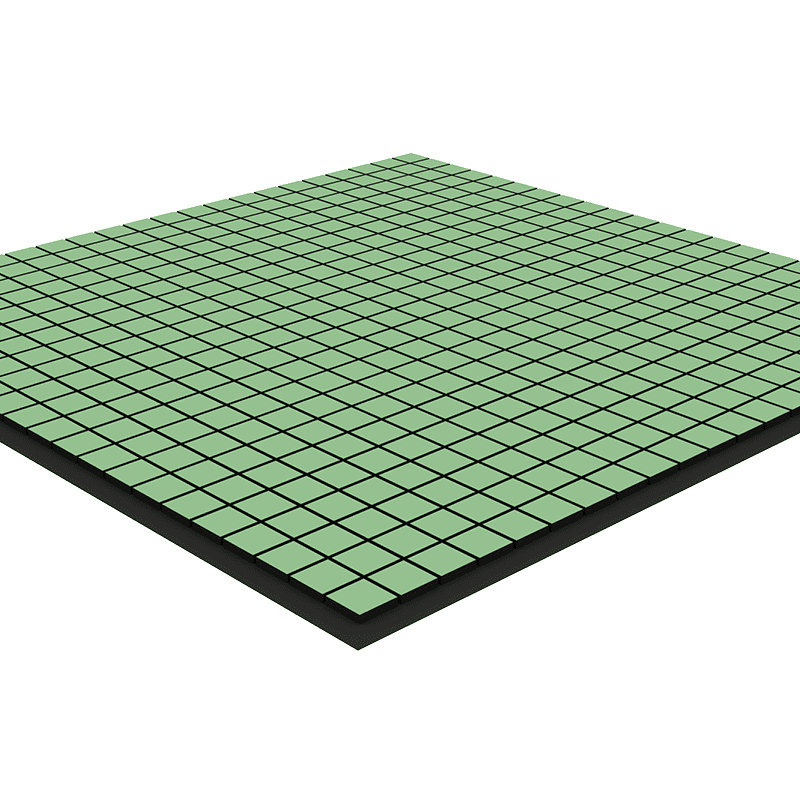

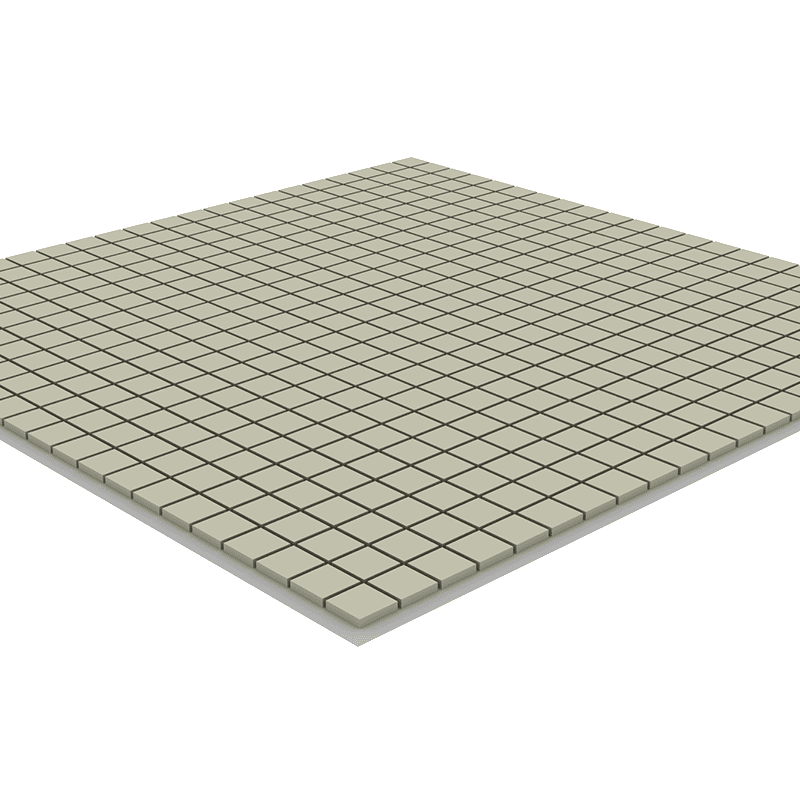

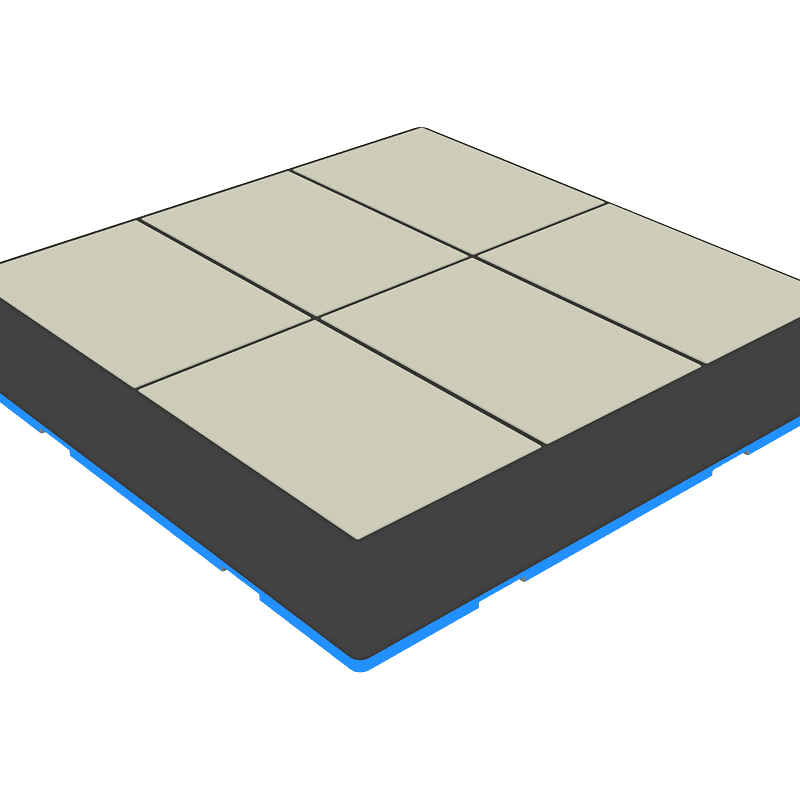

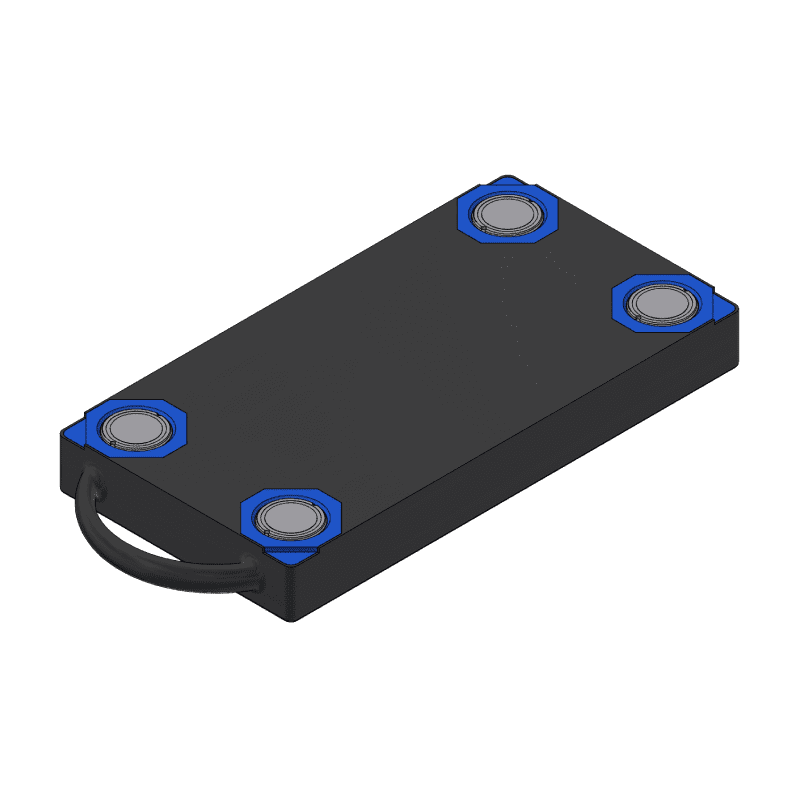

Introducing Magnefast™ Wear Liners

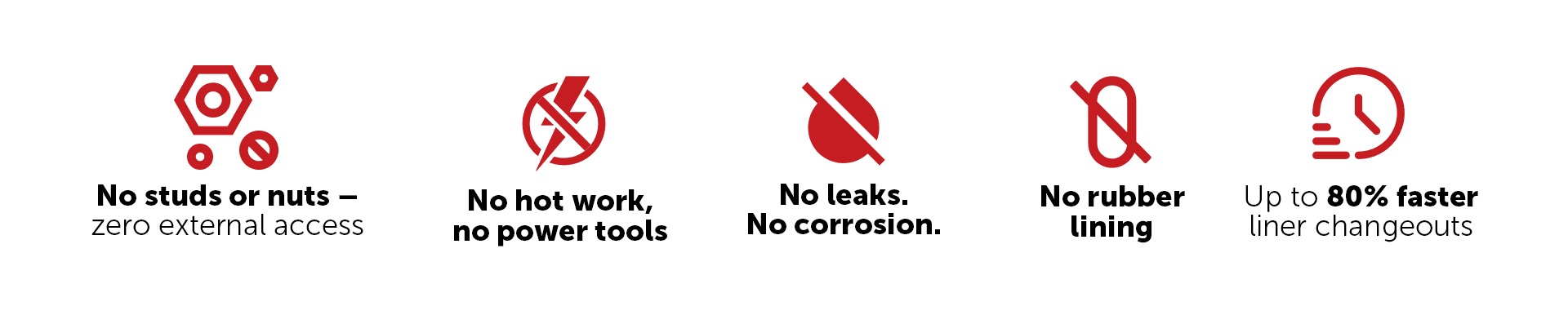

Magnefast™ is engineered to eliminate the weaknesses of traditional studded liners. Whether you’re upgrading existing wet plant such as slurry boxes, launders, wet chutes and underpans, or designing a new plant, Magnefast™ delivers:

- Up to 80% faster wear liner changeouts

- 50% less labour required

- Zero slurry leakage and corrosion risk

- No power tools or hot work needed

- Simplified wet plant design and retrofitting

Reduce downtime, increase safety, and boost your operational efficiency with a smarter wear liner solution. Ready to improve performance and safety?

Download our full Technical Bulletin below and discover how Magnefast™ can transform your wet plant maintenance and eliminate leakage for good.

For more information on how Elastotec’s innovative solutions can help address your site challenges, contact our team of experts today.

Download Technical Bulletin

Case Study: How an Iron Ore Mine Solved Recurring Lagging Failures

Cutting Downtime, Protecting Belts – The Elastotec Advantage At an Iron Ore mine in Western Au

Magnefast™: Faster, Safer Wear Liner Change-Outs

Cut downtime, boost safety, and extend liner life with magnetic wear liner innovation. Extended shut

Lagging Select: What Traditional Conveyor Designs Misses

Is your conveyor truly protected from belt and lagging damage — or just barely avoiding slip? Conv